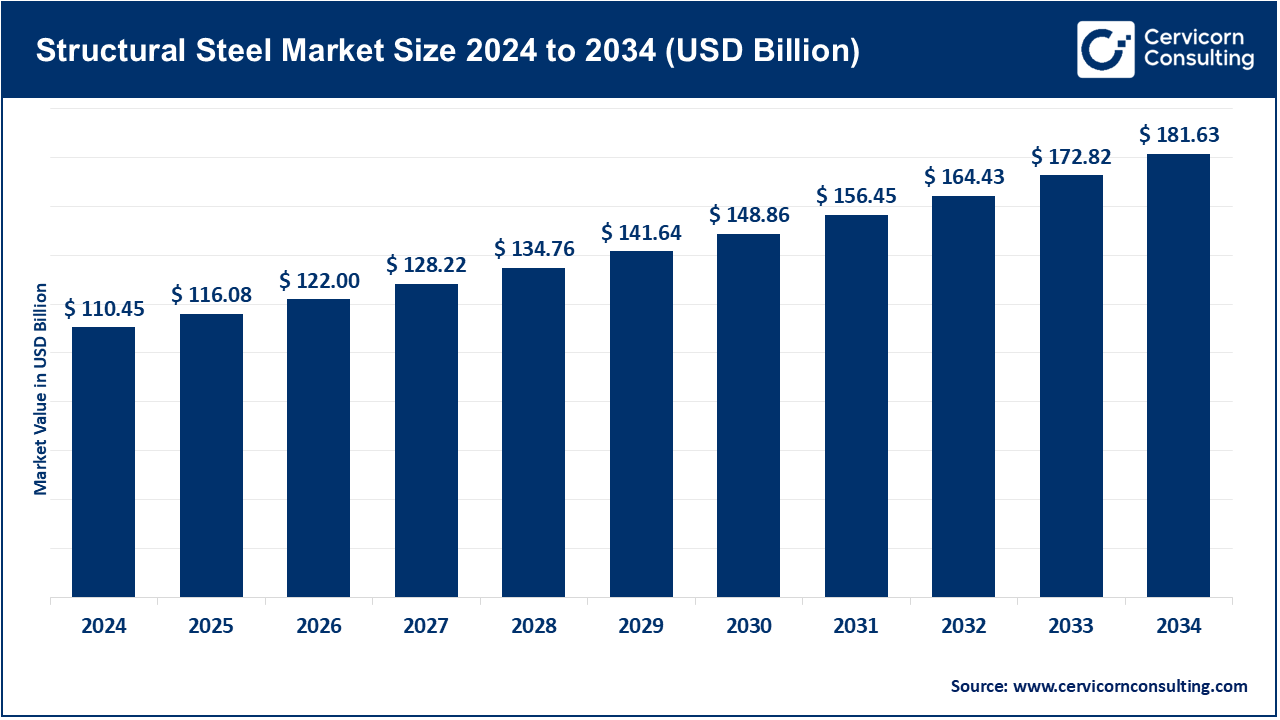

The global structural steel market size was valued at USD 110.45 billion in 2024 and is expected to surpass around USD 181.63 billion by 2034, expanding at a compound annual growth rate (CAGR) of 5.1% over the forecast period from 2025 to 2034. The global structural steel market, undergirded by several key factors, is growing. Rapid urban infrastructural developments, especially in emerging nations, stand out as one of the major factors. It is the immediate requirement for residential and commercial buildings brought about by urbanisation that boosts the demand of structural steel. On the infrastructure front, government-sponsored projects aiming at electricity generation plants, airports, and transportation networks are further accentuating the market growth.

Further, the use of structural steel is finding higher traction due to the increasing focus on green building practices. Steel is recyclable without any diminution of properties and thus compliments the green building certification systems and environmental norms. It is an eco-attribute that is gaining favour among developers keen on cutting down carbon footprints and spreading the message of circular economy. Moreover, these recent technological innovations on steel production and fabrication further enhance the efficiency of this material and reduce the costs of production. Mechanization and innovations in the field of high-strength, low-alloy steels, corrosion-resistant coatings, and fabrication processes help the evolution of structural steel to be of high efficiency and cost-effectiveness.

Top Structural Steel Exporters in 2024

| Country | Share, 2024 |

| China | 26.10% |

| Japan | 6.90% |

| South Korea | 6.20% |

| Germany | 5% |

| Turkey | 3.80% |

What is structural steel?

Structural steel is well known for its high strength-to-weight ratio, ease of fabrication, and adaptability for varied construction purposes. This ensures increased design flexibility and is deemed suitable for manufacturing via prefabrication, thus ensuring shorter construction timelines. It also holds a high compatibility level with other construction materials and can provide for exacting safety codes, making it a staple for contemporary engineering and architectural materials.

Globally, the structural steel market occupies a vital place under the construction and infrastructure industries. This sector forms the backbone of various applications-kills-a building, bridges, industrial facilities, and transportation systems. Structural steel means steel improperly allowed for making materials of construction in various shapes and sizes conceived of heavy loads and resistance to bending or deformation. Being versatile, strong, and recyclable, it finds application for structural frameworks and reinforcement.

Report Scope

| Area of Focus | Details |

| Market Size in 2025 | USD 116.08 Billion |

| Expected Market Size in 2034 | USD 181.63 Billion |

| Projected CAGR 2025 to 2034 | 5.1% |

| Dominant Region | Asia-Pacific |

| Key Segments | Product Type, Steel Type, End-Use Industry, Region |

| Key Companies | Tata Steel, ArcelorMittal, Evraz PLC, Baogang Group, Gerdau S.A., Nippon Steel Corporation, JSW Steel, POSCO, SAIL, Anshan Iron & Steel Group Corporation |

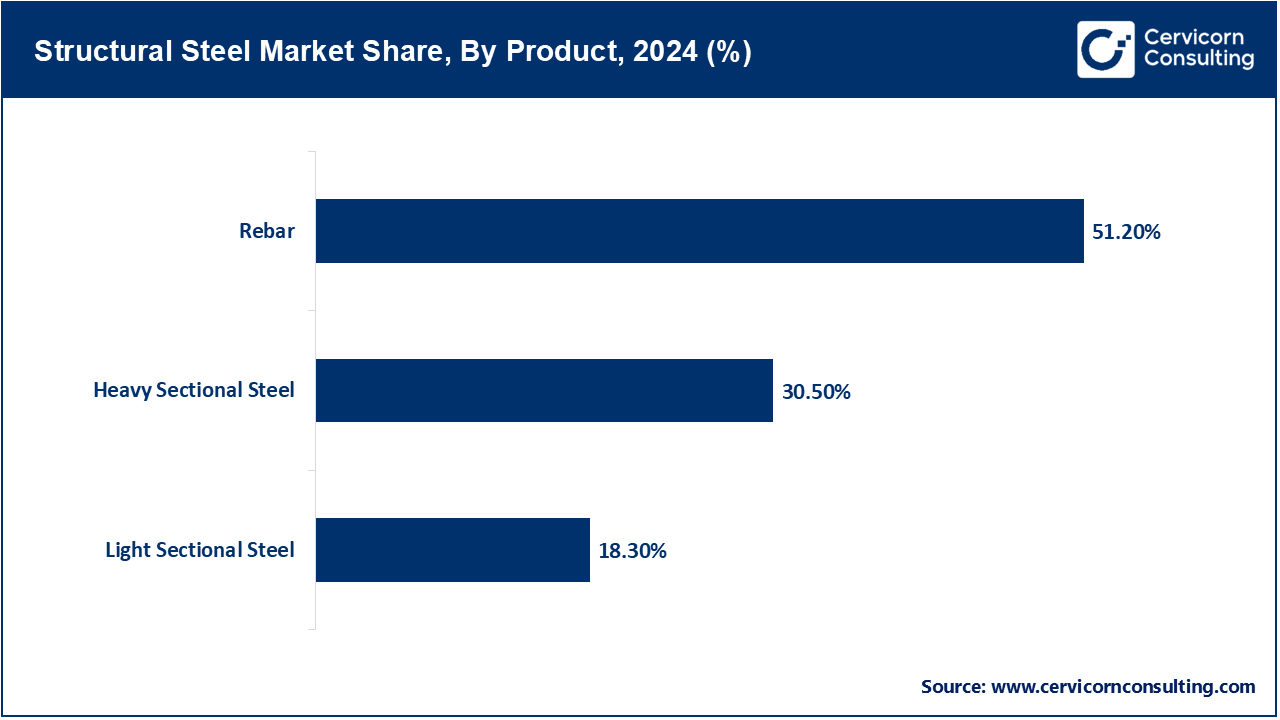

Heavy Sectional Steel: The heavy sectional steel segment has captured highest revenue share. Heavy section steel has very large structural sections such as I-beams, H-beams, wide flange beams over which building framework is constructed; hence it should be considered for large-scale industrial plants, bridges, shipyards, and multi-story complexes. Not only are these designed to carry very heavy loads, but they also confer structural stability and resistance to deformation on the structure. The heavy sections can support heavy vertical and lateral loads and are preferred for mega infrastructure and commercial development projects. The market for heavy-section steel is aided by rapid industrialization, mounting investments in transportation and energy infrastructures along with technological improvements in steel fabrication. However, very high costs and cumbersome logistics may prevent their application in smaller and medium-sized projects. Regardless, developing countries with massive-scale infrastructure development plans remain the main consumers of this product.

Light Sectional Steel: HSS is basically a tubular steel section used in structural steel framing. It is generally differentiated depending on the size/type of the section; thus, the term is called for short, whereas a structural steel section basically includes angles, channels, beams, and plates. These materials are greatly preferred because they are easy to handle, lightweight, and meet modern design standards. By virtue of lighter steel sections, assembly can be faster, and construction costs and construction time reduced. Being highly recyclable and energy-efficient, light steel sections are viewed as a solution for green building. Operations in the modular-building and DIY spheres are also seeing increased applications for light steel sections. With growing urban housing demands and changing construction norms focusing on sustainability, the demand for light steel sections is, therefore, anticipated to increase, especially in space-constrained urban areas.

Rebar: In construction via reinforced concrete, iron bars or reinforcing bars are used as products to augment the tensile strength of a concrete structure. They apply in foundations, columns, roads, bridges, dams, or tunnels. Rebarnorton steel, carbon type, comes in diameters, surface deformations, categories, and grades, depending on the needs of the structure. Rapid urbanization, government infrastructure development programs, and increase in residential and commercial constructions are the major factors that drive the demand for rebars worldwide. Being relatively cheaper as compared to other construction metals, rebars are abundantly available, hence their essential role in structural steel. Furthermore, growing interest in corrosion-resistant and earthquake-resistant rebars in both developed and developing countries further enhances its growth.

Hot-Rolled Steel: The hot-rolled steel segment has dominated the market. Hot rolling of steel is a very high-temperature treatment given to steel so that it becomes more malleable to shape and form. Strength and cheapness have made this steel type quite popular with construction, railroads, and manufacturing industries. It is perfect for structural components like beams, angles, and channels. Rougher surface finishes and relaxed tolerances are fine for heavy works like bridges, highways, and building frameworks where precision isn't required. Steel in this category is cheap, available in huge sizes, and with fast turnaround times-somewhat unusual in the structural steel market, especially for infrastructure, industrial, and commercial sectors.

Cold-Rolled Steel: Cold-rolled steel is produced through further processing of hot-rolled steel in room temperature, thereby producing a finer surface finish, tighter tolerances, and higher strength. It finds application wherever dimensional accuracy is important, and often ornamental finish is also given much consideration, as in precision structural parts, automotive frames, and appliances. It sits more expensive than hot-rolled steel but enhanced mechanical properties and smooth finish benefit high-performance engineering applications. Cold-rolled steel is carving out a niche in industries that require both strength and formability; however, these markets are smaller compared to the structural sector, principally on account of the high prices and smaller sizes available for cold-rolled steel.

Carbon-Manganese Steel: Carbon-Manganese steel has carbon and manganese to impart strength and hardenability and retain weldability. It is broadly used in construction and structural application due to the good balance of price, strength, and ductility. Suitable for buildings, pipelines, storage tanks, and bridges, the manganese content also improves the toughness and impact resistance, thereby making the material more dependable for dynamic loads. Its versatility and economy have made it one of the most common steels in structural applications worldwide, but it does not have enhanced corrosion resistance and performance in extreme conditions as advanced types of steel like HSLA.

High-Strength Low-Alloy (HSLA) Steel: HSLA steels are developed to have better strength-to-weight ratio, along with adequate formability and weldability characteristics. Small amounts of alloying elements like copper, vanadium, or niobium will be present in it to ameliorate the mechanical properties and corrosion resistance. These grades of steels are useful primarily in applications that call for performance and weight considerations such as high-rise buildings, bridges, and offshore structures. Because they are very strong, very light structural members are possible, which otherwise would not have been possible to carry loads. Being progressively more expensive than regular carbon steels, the HSLA steels are increasingly being exploited in modern infrastructure projects in the interest of longevity and sustainable design through less material usage.

Heat-Treated Carbon/Alloy Steel: The heat treatment of carbon and alloy steels alongside tempering and quenching gives the heat-treated steels their properties of strength, hardness, and resistance to fatigue. These steels are suitable for heavy-load structural applications and specialized industrial uses such as cranes, heavy machinery, and structural members in earthquake-resistant or high-stress applications. Suitable alloying elements, such as chromium, molybdenum, or nickel, may be added to improve toughness and corrosion resistance. Heat treatment increases the value of steels due to the elaborate processing involved. Therefore, due to its superior mechanical properties, heat-treated steel is reserved for use in critical infrastructure and high-performance engineering where structural steels are marginal in choice.

Construction: The construction segment accounted for a highest revenue share in the market. Difference resultant of construction sector consumes the maximum supply of structural steel, with strength being high, weight very low, flexibility good, and durability present in good measure. Structural steel is used in high-rise buildings, bridges, warehouses, and residential complexes. Rapid urbanization, increasing interventions by population, and infrastructure malleability in commercial terms further pushed market growth. Emerging economies are heavily investing in smart cities and transportation infrastructures, thereby enhancing further the demand. The market for steel increased further because of sustainable and green building materials. Prefabricated steel structures are gaining momentum for lessening construction time and cost. Earthquake-resistant and fire-proof designs are also enhancing the demand for steel.

Oil & Gas: In the oil & gas industry, structural steel is indispensable in building offshore platforms, pipeline systems, refineries, and drilling rigs. It resists corrosion in harsh atmospheres and weathers, pressure, and temperature extremes that are intolerable to his construction. With rising global demand, especially for offshore and deep-sea exploration, the need for stronger infrastructures supports steel consumption. The major contributions in demand are due to investments coming from the Middle East and North America into upstream and midstream operations. Lastly, the ability of steel to be fabricated into modular and custom designs brings along with itself a key impetus for the development of the sector.

Energy & Power: Structural steel plays an important role in facilities that generate power-like wind turbines, transmission towers, nuclear plants, and hydropower stations. The shift in demand toward renewable energy has created greater demand for durable high-performance materials. Steel being strong, malleable, and having a long lifecycle makes it ideal to stand up to heavy equipment or large installations. In the wind energy sector, structural steel finds its use in constructing towers and internal frameworks. Heavy investments in energy infrastructure, especially in the Asian and European regions, would thus provide a lot of opportunities for steel producers. Government efforts to modernize the grid and push energy security are the other growth factor in this segment.

Automotive & Transportation: Structural steel applications are used in chassis, body frames, railway tracks, and heavy vehicles in automotive and transportation industries. Considering the energy efficiency and emission regulations, structural steel provides tensile strength and safety, yet lighter in weight. Railway and highway applications demand structural steel for superior longevity and endurance under heavy workloads. The global development of electric vehicles (EVs) and increased rail connectivity projects are further upraising demand for steel. Further, high-strength and low-weight steel grades are facilitating greater penetration of steel in the new-age automotive industry, where performance, safety, and fuel efficiency are paramount considerations.

Shipbuilding: Depending upon the grade, structural steel is applied by shipyards in the construction of hulls, decks, and offshore erections due to corrosion resistance and load-bearing capacity. This kind of steel should be able to stand the rigors of a marine environment for naval vessels, cargo ships, and oil tankers. As maritime trade expands globally and new shipbuilding centres grow in the Asia-Pacific, primarily South Korea and China, steel consumption in this segment is on the rise. The introduction of new steel grades to further enhance life span and reduce maintenance only add to its appeal. Structural steel for shipbuilding looks strong growth because of addition in LNG carrier demand and green shipping initiatives.

Mining & Heavy Machinery: Structural steel is a very significant component in the mining and heavy engineering sector for the purpose of fabricating excavators, bulldozers, and parallel infrastructure within the mine. High stress and abrasion load-bearing factor make it appropriate for harsh, high-impact work. Increased demand for metals and minerals has kept mining activities in regions like Latin America, Africa, and Australia on the rise, thus driving steel demand. Heavy machinery also utilizes high-strength steel to achieve operational efficiency and safety. Automation and an increase in innovation of mining equipment are derived to higher demand of steel, as structural steel provides the reliability required for more sophisticated mechanical operations.

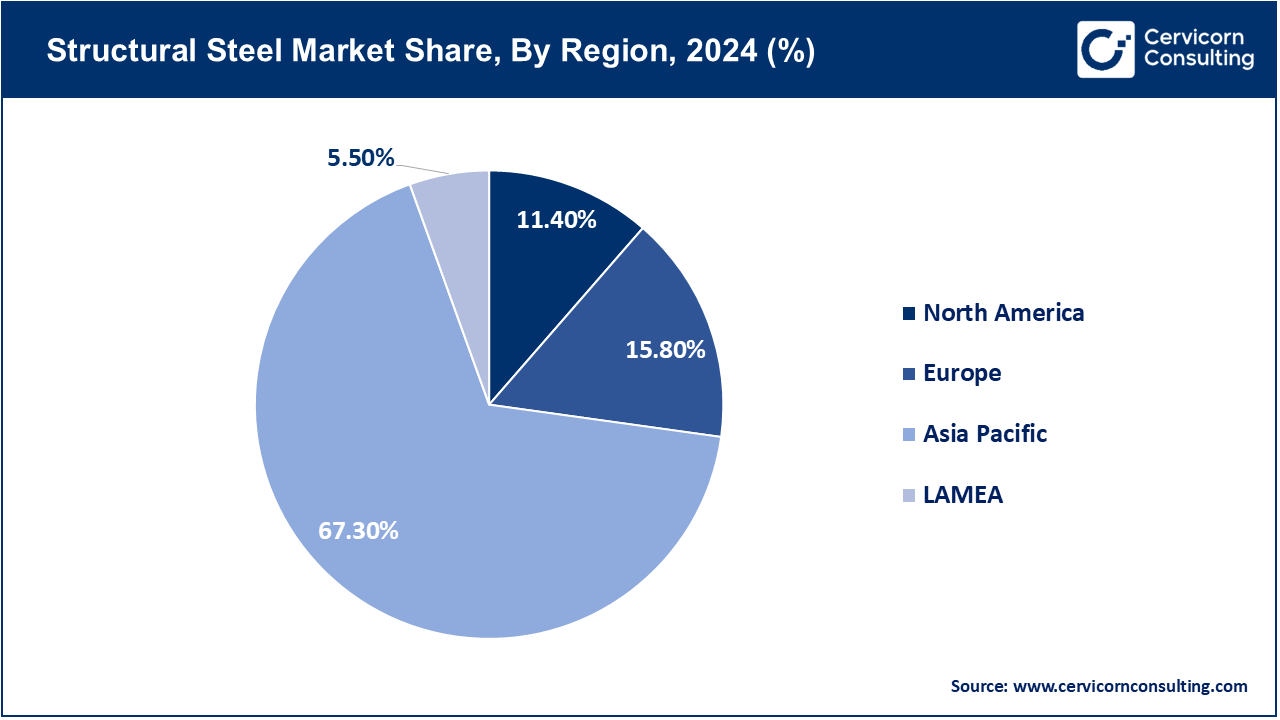

The structural steel market is segmented into several key regions: North America, Europe, Asia-Pacific, and LAMEA (Latin America, Middle East, and Africa). Here’s an in-depth look at each region.

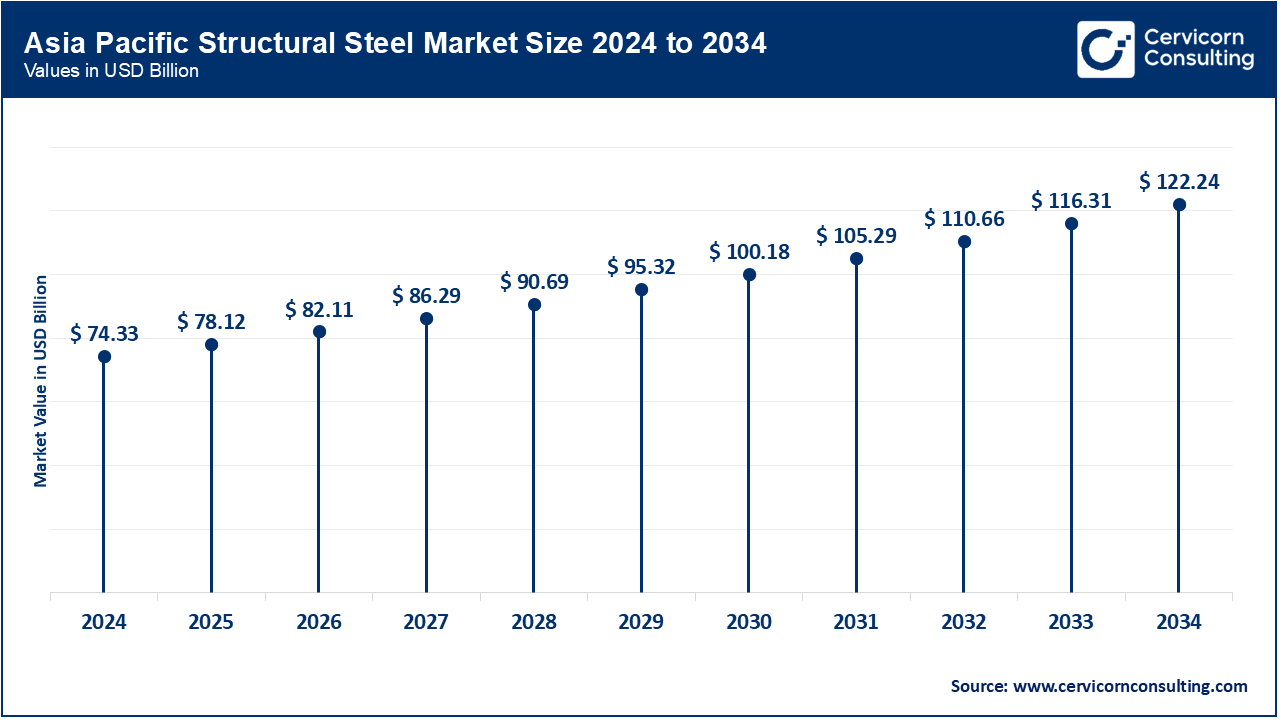

Asia-Pacific is a major global market owing to fast industrialization, urbanization, and heavy investments in infrastructure. China, having the greatest steel-production capacity with government-based projects such as the Belt and Road Initiative, leads the market. India comes in second due to heavy infrastructure development, smart city projects, and housing schemes. Southeast Asian countries experience good demand with commercial and residential constructions on the rise for them. Production and consumption are further increased by the region's competitive labour costs, availability of raw material, and good government policies. Investments in transportation, renewable energy, and manufacturing ensure further services to the growth of the market. Advances in steel manufacturing technologies, coupled with stronger adoption of prefabricated construction, especially in Japan and Korea, also keep on supporting the regional dominance. Therefore, Asia-Pacific is still the fastest-growing and most influential market for structural steel around the world.

Commercial building, energy infrastructure, and industrial development are some of the fields with healthy demand, thus taking the significant share of the North American market. The United States plays an important role in rehabilitating existent infrastructure, generating clean energy, and urban redevelopment projects on a large scale. Recently, demand for steel has increased because of the Infrastructure Investment and Jobs Act in the U.S. for steel used in roadways, bridges, and public buildings. Steady demand for energy and mining industries, especially in provinces like Alberta, supports the market in Canada. The region is also well-known for advanced steel fabrication technologies, and from the green building code perspective, working toward sustainable construction. The regional competitiveness could be affected by high labour costs and a high dependence on steel importations. That said, with healthy consumption in the domestic market and constant waves of investment in construction and infrastructure, the region continues to be a great player in the structural steel scene worldwide.

Europe market is fuelled by industrial modernization, environmental policies, economical refurbishing of historic and public infrastructure. Germany, France, UK, and Italy being the major economies, promote the use of sustainable construction practices and circular economy concepts alongside energy-efficient building materials such as structural steel. Furthermore, the European green policies provide an impetus for steel recycling and the use of low-carbon technologies in steel production. The investments in smart cities and renewable energy infrastructures generate demand for steel as well. Some environmental norms and the higher cost of production take precedence against competitiveness vis-à-vis Asia. The automotive and transportation industries, especially in Germany, are also supportive of steel consumption. The Ukrainian conflict and price volatility of energy have also affected the European steel supply chain, thereby encouraging onshoring and supply chain resilience. Overall, Europe remains a mature yet evolutionary market for structural steel, with innovation and sustainability receiving top priority.

Structural steel enjoys slow but steady growth as an emerging market in the LAMEA zones. In Latin America, countries such as Brazil and Mexico focus on public housing and transportation networks, raising the demand for structural steels. Further eastward, the Middle East, headed by the UAE and Saudi Arabia, witness massive infrastructure expansion as part of their economic diversification plans, with NEOM and Vision 2030 being the prime contributors to steel demand. Africa is experiencing a kind of a slow growth because of government initiatives in infrastructure and urban development, led by Nigeria and South Africa. The political instability, fluctuating economic conditions, and limited steel-manufacturing opportunities within it are drawbacks faced by the region. This causes steel and raw materials to be imported, the price and availability of which keep fluctuating. However, the greater growth potential of LAMEA comes from untapped markets together with growing foreign direct investments into construction and industrial sectors.

Market Segmentation

By Product Type

By Steel Type

By End-Use Industry

By Region

Chapter 1 Market Introduction and Overview

1.1 Market Definition and Scope

1.1.1 Overview of Structural Steel

1.1.2 Scope of the Study

1.1.3 Research Timeframe

1.2 Research Methodology and Approach

1.2.1 Methodology Overview

1.2.2 Data Sources and Validation

1.2.3 Key Assumptions and Limitations

Chapter 2 Executive Summary

2.1 Market Highlights and Snapshot

2.2 Key Insights by Segments

2.2.1 By Product Type Overview

2.2.2 By Steel Type Overview

2.2.3 By End-Use Industry Overview

2.3 Competitive Overview

Chapter 3 Global Impact Analysis

3.1 Russia-Ukraine Conflict: Global Market Implications

3.2 Regulatory and Policy Changes Impacting Global Markets

Chapter 4 Market Dynamics and Trends

4.1 Market Dynamics

4.1.1 Market Drivers

4.1.1.1 Superior Strength-to-Weight Ratio of Structural Steel

4.1.1.2 Faster Construction Timelines with Modular Steel Systems

4.1.1.3 Recyclability and Environmental Benefits of Steel

4.1.2 Market Restraints

4.1.2.1 Unpredictable Iron Ore and Scrap Supply Dynamics

4.1.2.2 Stringent Sustainability Compliance Mandates

4.1.2.3 Cost Barriers Due to Energy-Intensive Production

4.1.3 Market Challenges

4.1.3.1 Navigating Fluctuating International Trade Policies

4.1.3.2 Managing Construction Delays Due to Steel Shortages

4.1.3.3 Adapting to Rapid Shifts in Design Standards and Codes

4.1.4 Market Opportunities

4.1.4.1 Rising Demand for Earthquake-Resistant Structures

4.1.4.2 Integration of Smart Technologies in Steel Fabrication

4.1.4.3 Government-Backed Urban Renewal Projects

4.2 Market Trends

Chapter 5 Premium Insights and Analysis

5.1 Global Structural Steel Market Dynamics, Impact Analysis

5.2 Porter’s Five Forces Analysis

5.2.1 Bargaining Power of Suppliers

5.2.2 Bargaining Power of Buyers

5.2.3 Threat of Substitute Products

5.2.4 Rivalry among Existing Firms

5.2.5 Threat of New Entrants

5.3 PESTEL Analysis

5.4 Value Chain Analysis

5.5 Product Pricing Analysis

5.6 Vendor Landscape

5.6.1 List of Buyers

5.6.2 List of Suppliers

Chapter 6 Structural Steel Market, By Product Type

6.1 Global Structural Steel Market Snapshot, By Product Type

6.1.1 Market Revenue (($Billion) and Growth Rate (%), 2022-2034

6.1.1.1 Heavy Sectional Steel

6.1.1.2 Light Sectional Steel

6.1.1.3 Rebar

Chapter 7 Structural Steel Market, By Steel Type

7.1 Global Structural Steel Market Snapshot, By Steel Type

7.1.1 Market Revenue (($Billion) and Growth Rate (%), 2022-2034

7.1.1.1 Hot-Rolled Steel

7.1.1.2 Cold-Rolled Steel

7.1.1.3 Carbon-Manganese Steel

7.1.1.4 High-Strength Low-Alloy (HSLA) Steel

7.1.1.5 Heat-Treated Carbon/Alloy Steel

Chapter 8 Structural Steel Market, By End-Use Industry

8.1 Global Structural Steel Market Snapshot, By End-Use Industry

8.1.1 Market Revenue (($Billion) and Growth Rate (%), 2022-2034

8.1.1.1 Construction

8.1.1.2 Oil & Gas

8.1.1.3 Energy & Power

8.1.1.4 Automotive & Transportation

8.1.1.5 Shipbuilding

8.1.1.6 Mining & Heavy Machinery

8.1.1.7 Others

Chapter 9 Structural Steel Market, By Region

9.1 Overview

9.2 Structural Steel Market Revenue Share, By Region 2024 (%)

9.3 Global Structural Steel Market, By Region

9.3.1 Market Size and Forecast

9.4 North America

9.4.1 North America Structural Steel Market Revenue, 2022-2034 ($Billion)

9.4.2 Market Size and Forecast

9.4.3 North America Structural Steel Market, By Country

9.4.4 U.S.

9.4.4.1 U.S. Structural Steel Market Revenue, 2022-2034 ($Billion)

9.4.4.2 Market Size and Forecast

9.4.4.3 U.S. Market Segmental Analysis

9.4.5 Canada

9.4.5.1 Canada Structural Steel Market Revenue, 2022-2034 ($Billion)

9.4.5.2 Market Size and Forecast

9.4.5.3 Canada Market Segmental Analysis

9.4.6 Mexico

9.4.6.1 Mexico Structural Steel Market Revenue, 2022-2034 ($Billion)

9.4.6.2 Market Size and Forecast

9.4.6.3 Mexico Market Segmental Analysis

9.5 Europe

9.5.1 Europe Structural Steel Market Revenue, 2022-2034 ($Billion)

9.5.2 Market Size and Forecast

9.5.3 Europe Structural Steel Market, By Country

9.5.4 UK

9.5.4.1 UK Structural Steel Market Revenue, 2022-2034 ($Billion)

9.5.4.2 Market Size and Forecast

9.5.4.3 UK Market Segmental Analysis

9.5.5 France

9.5.5.1 France Structural Steel Market Revenue, 2022-2034 ($Billion)

9.5.5.2 Market Size and Forecast

9.5.5.3 France Market Segmental Analysis

9.5.6 Germany

9.5.6.1 Germany Structural Steel Market Revenue, 2022-2034 ($Billion)

9.5.6.2 Market Size and Forecast

9.5.6.3 Germany Market Segmental Analysis

9.5.7 Rest of Europe

9.5.7.1 Rest of Europe Structural Steel Market Revenue, 2022-2034 ($Billion)

9.5.7.2 Market Size and Forecast

9.5.7.3 Rest of Europe Market Segmental Analysis

9.6 Asia Pacific

9.6.1 Asia Pacific Structural Steel Market Revenue, 2022-2034 ($Billion)

9.6.2 Market Size and Forecast

9.6.3 Asia Pacific Structural Steel Market, By Country

9.6.4 China

9.6.4.1 China Structural Steel Market Revenue, 2022-2034 ($Billion)

9.6.4.2 Market Size and Forecast

9.6.4.3 China Market Segmental Analysis

9.6.5 Japan

9.6.5.1 Japan Structural Steel Market Revenue, 2022-2034 ($Billion)

9.6.5.2 Market Size and Forecast

9.6.5.3 Japan Market Segmental Analysis

9.6.6 India

9.6.6.1 India Structural Steel Market Revenue, 2022-2034 ($Billion)

9.6.6.2 Market Size and Forecast

9.6.6.3 India Market Segmental Analysis

9.6.7 Australia

9.6.7.1 Australia Structural Steel Market Revenue, 2022-2034 ($Billion)

9.6.7.2 Market Size and Forecast

9.6.7.3 Australia Market Segmental Analysis

9.6.8 Rest of Asia Pacific

9.6.8.1 Rest of Asia Pacific Structural Steel Market Revenue, 2022-2034 ($Billion)

9.6.8.2 Market Size and Forecast

9.6.8.3 Rest of Asia Pacific Market Segmental Analysis

9.7 LAMEA

9.7.1 LAMEA Structural Steel Market Revenue, 2022-2034 ($Billion)

9.7.2 Market Size and Forecast

9.7.3 LAMEA Structural Steel Market, By Country

9.7.4 GCC

9.7.4.1 GCC Structural Steel Market Revenue, 2022-2034 ($Billion)

9.7.4.2 Market Size and Forecast

9.7.4.3 GCC Market Segmental Analysis

9.7.5 Africa

9.7.5.1 Africa Structural Steel Market Revenue, 2022-2034 ($Billion)

9.7.5.2 Market Size and Forecast

9.7.5.3 Africa Market Segmental Analysis

9.7.6 Brazil

9.7.6.1 Brazil Structural Steel Market Revenue, 2022-2034 ($Billion)

9.7.6.2 Market Size and Forecast

9.7.6.3 Brazil Market Segmental Analysis

9.7.7 Rest of LAMEA

9.7.7.1 Rest of LAMEA Structural Steel Market Revenue, 2022-2034 ($Billion)

9.7.7.2 Market Size and Forecast

9.7.7.3 Rest of LAMEA Market Segmental Analysis

Chapter 10 Competitive Landscape

10.1 Competitor Strategic Analysis

10.1.1 Top Player Positioning/Market Share Analysis

10.1.2 Top Winning Strategies, By Company, 2022-2024

10.1.3 Competitive Analysis By Revenue, 2022-2024

10.2 Recent Developments by the Market Contributors (2024)

Chapter 11 Company Profiles

11.1 Tata Steel

11.1.1 Company Snapshot

11.1.2 Company and Business Overview

11.1.3 Financial KPIs

11.1.4 Product/Service Portfolio

11.1.5 Strategic Growth

11.1.6 Global Footprints

11.1.7 Recent Development

11.1.8 SWOT Analysis

11.2 ArcelorMittal

11.3 Evraz PLC

11.4 Baogang Group

11.5 Gerdau S.A.

11.6 Nippon Steel Corporation

11.7 JSW Steel

11.8 POSCO

11.9 SAIL

11.10 Anshan Iron & Steel Group Corporation