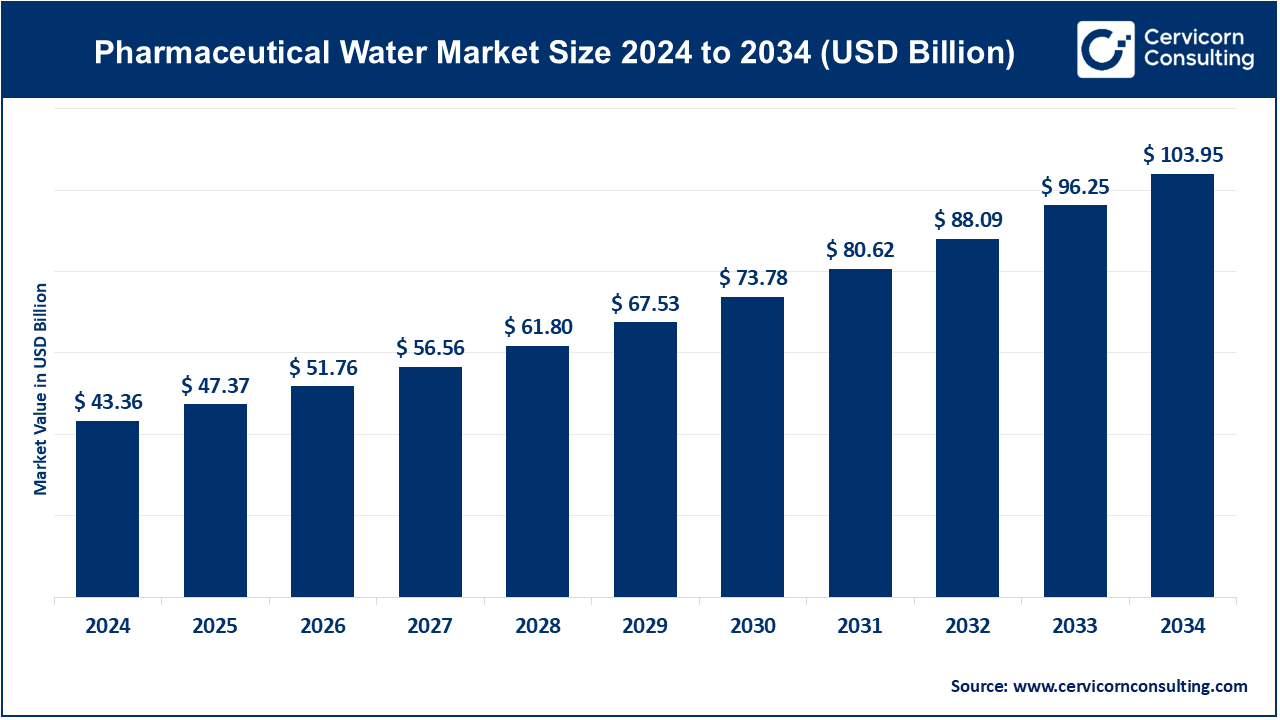

The global pharmaceutical water market size was valued at USD 47.37 billion in 2025 and is forecasted to exceed around USD 111.96 billion by 2035, growing at a compound annual growth rate (CAGR) of 8.98% from 2026 to 2035. The pharmaceutical water market has seen substantial demand due to its essential role in drug manufacturing, formulation, and laboratory applications. With increasing global concerns regarding product safety and the rising production of biopharmaceuticals, water quality has become a crucial focus for pharmaceutical manufacturers. The adoption of advanced filtration and purification technologies has also driven innovation, with companies offering customized solutions tailored to meet stringent regulatory standards for water used in drug production. Moreover, the growing emphasis on regulatory compliance is pushing companies to invest in reliable water treatment systems, fostering market growth. The market is influenced by factors such as technological advancements in water purification systems, government regulations on water quality, and the rising production of injectables, biologics, and vaccines.

Pharmaceutical water is a critical component in the pharmaceutical industry, serving as a raw material, ingredient, and solvent in the processing, formulation, and manufacture of pharmaceutical products, active pharmaceutical ingredients (APIs), and intermediates. It is utilized in various stages, including synthesis, production of finished products, and as a cleaning agent for rinsing vessels, equipment, and primary packaging materials. The quality of pharmaceutical water is paramount, as it must meet stringent standards to ensure the safety and efficacy of pharmaceutical products. Regulatory bodies, such as the U.S. Food and Drug Administration (FDA), have established guidelines for water used in pharmaceutical applications, emphasizing the removal of minerals, organics, and microbes to prevent contamination.

Report Scope

| Area of Focus | Details |

| Market Size in 2026 | USD 51.76 Billion |

| Market Growth Rate | CAGR of 8.98% from 2026 to 2035 |

| Market Size by 2035 | USD 111.96 Billion |

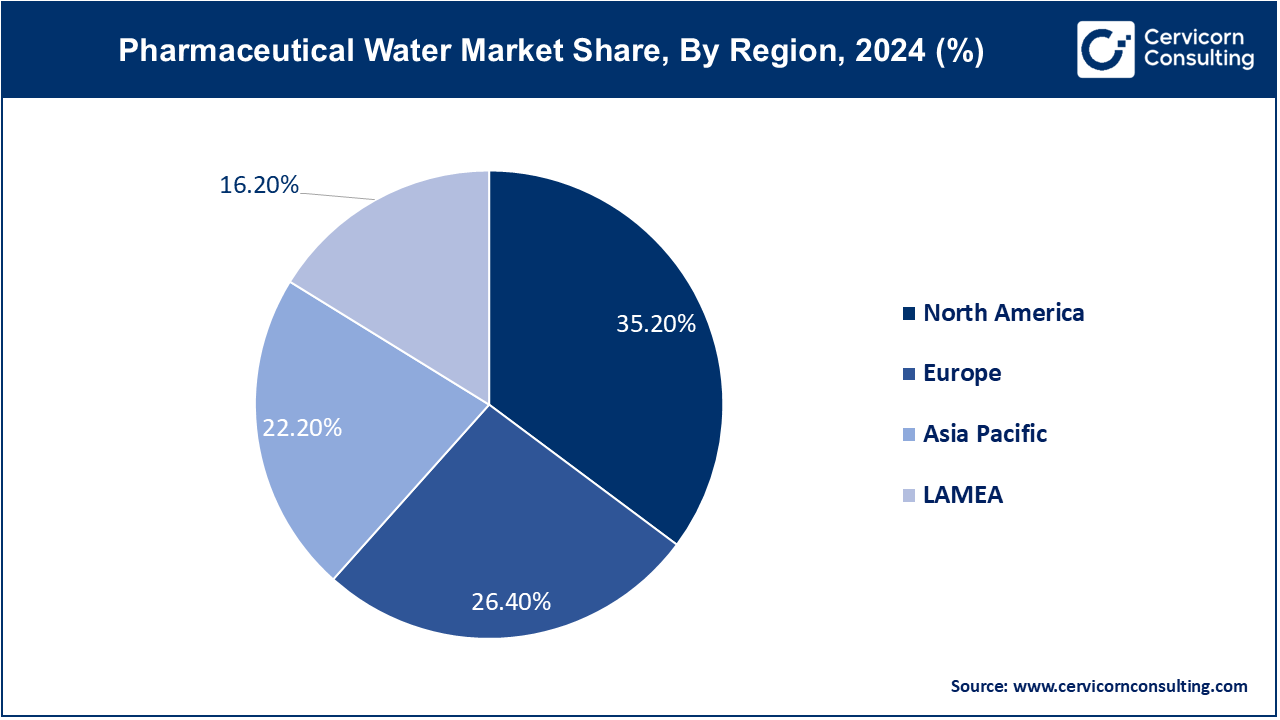

| Largest Market | North America |

| Fastest Growing Market | Asia Pacific |

| Segment Coverage | By Type, Technology, Application and Regions |

Global Pandemic Preparedness

Increasing Outsourcing Trends

High Capital Investment

The significant upfront costs of acquiring and installing advanced water purification systems, along with ongoing operational expenses for maintenance and upgrades, can strain the financial resources of pharmaceutical companies. This financial barrier may delay or limit investments in modernizing water treatment infrastructure.

Complex Regulatory Landscape

Advanced Water Purification Technologies

Expansion in Emerging Markets

Water Quality Variability

Water Scarcity and Resource Management

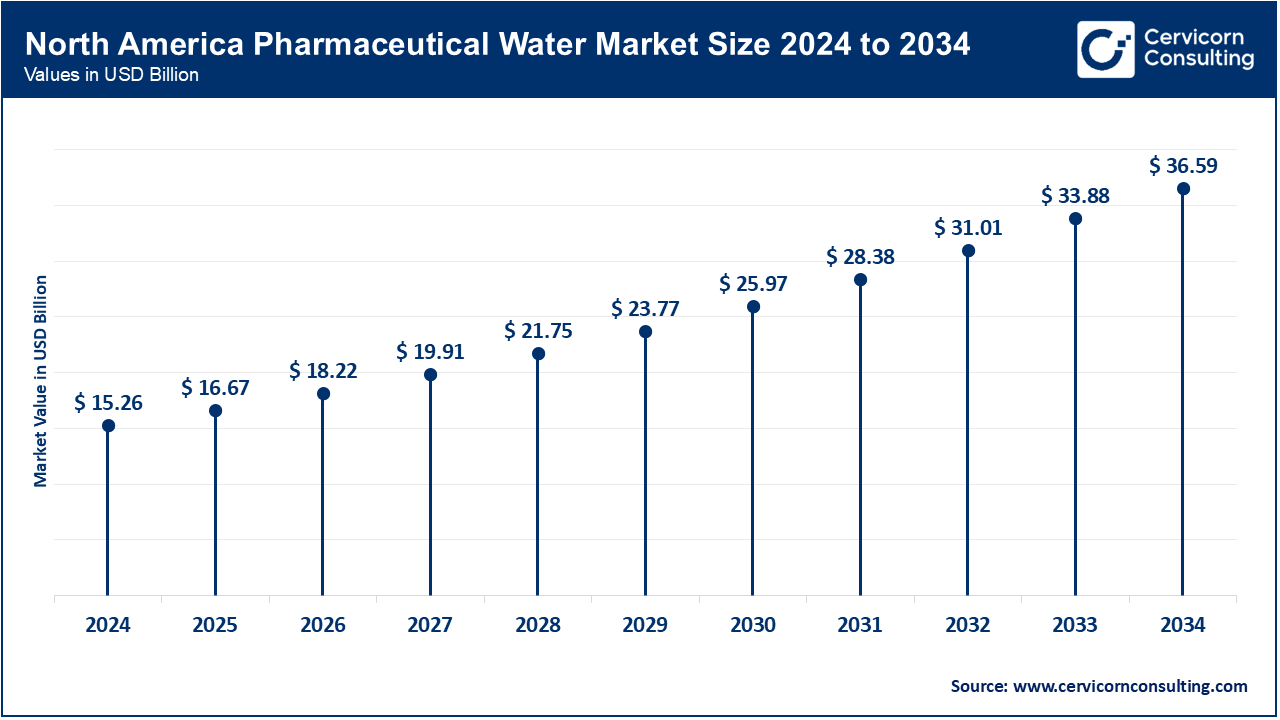

In North America, there is a strong focus on implementing advanced water purification technologies to meet stringent regulatory requirements. North America market size is expected to reach around USD 39.18 billion by 2035 increasing from USD 16.58 billion in 2025. Trends include increased investment in sustainable water management practices and adoption of innovative filtration and disinfection technologies to ensure pharmaceutical-grade water quality.

The Asia-Pacific region experiences rapid pharmaceutical industry growth and increasing demand for high-quality water in drug manufacturing. Asia Pacific market size is calculated at USD 10.42 billion in 2025 and is projected to grow around USD 24.63 billion by 2035. Trends include expanding pharmaceutical production capacities, adoption of cost-effective water treatment solutions, and regulatory harmonization efforts to align with international standards, fostering market expansion and technological innovation.

Europe emphasizes sustainable water use and compliance with strict environmental regulations. Europe market size is measured at USD 12.32 billion in 2025 and is expected to grow around USD 29.11 billion by 2035. Trends include the integration of smart water management systems, such as IoT-enabled monitoring and predictive maintenance, to optimize water usage efficiency and reduce operational costs in pharmaceutical manufacturing.

LAMEA(Latin America, Middle East, and Africa) countries focus on improving healthcare infrastructure and regulatory frameworks to support pharmaceutical manufacturing. LAMEA market size is forecasted to reach around USD 19.05 billion by 2035 from USD 8.05 billion in 2025. Trends include investment in water infrastructure development, partnerships with international manufacturers for technology transfer, and local capacity building in water treatment technologies to enhance market competitiveness and sustainability.

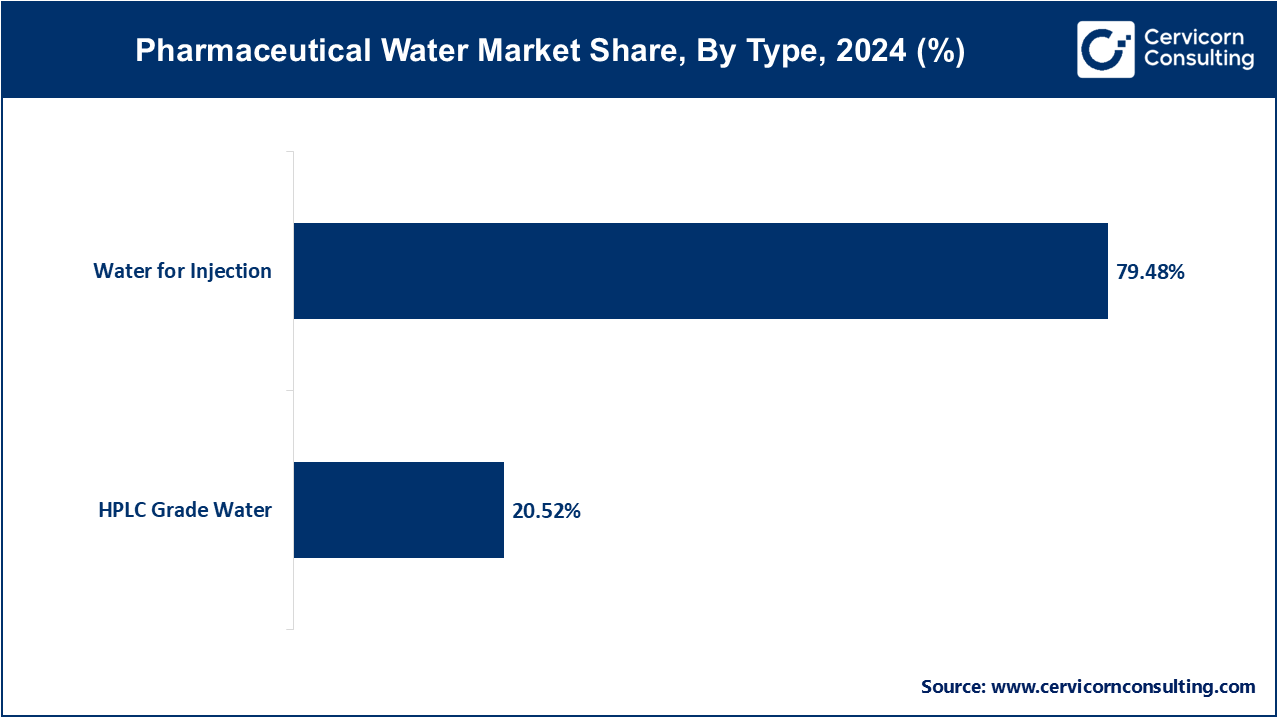

HPLC Grade Water: High Performance Liquid Chromatography (HPLC) Grade Water is purified to meet stringent quality standards suitable for analytical and chromatographic applications in pharmaceutical laboratories. High Performance Liquid Chromatography (HPLC) grade water segment has captured market share of 20.52% in 2025. Trends include increasing demand for ultra-pure water quality to ensure accurate and reproducible analytical results, driven by advancements in analytical techniques and the need for precise pharmaceutical testing.

Water for Injection (WFI): Water for Injection is produced using techniques such as distillation or membrane filtration to meet rigorous standards for injectable pharmaceuticals. In 2025 the water for injection segment has covered highest market share of 79.48%. Trends focus on enhancing production efficiency, ensuring compliance with global pharmacopeial standards, and adopting advanced purification technologies to meet growing demand for sterile and pyrogen-free water in parenteral drug formulations.

Membrane Filtration: Utilizes semi-permeable membranes to remove particles, microorganisms, and dissolved solids from water, ensuring purity for pharmaceutical applications. Trend: Increasing adoption due to efficiency, scalability, and compatibility with sustainable practices.

Distillation: Involves boiling water to produce steam, which is condensed and collected as purified water. Trend: Essential for producing Water for Injection (WFI) due to reliability and compliance with regulatory standards.

Electrodeionization (EDI): Removes ions from water using ion-exchange membranes and electrical current, producing high-purity water without chemical regeneration. Trend: Growing preference for continuous operation and reduced chemical usage.

UV Oxidation: Utilizes ultraviolet light to disinfect water by disrupting microbial DNA. Trend: Rising use for microbial control in pharmaceutical water systems due to effectiveness and environmental benefits.

Others: Includes technologies like reverse osmosis (RO) for selective filtration and ozonation for disinfection, adapting to specific purity and production needs in pharmaceutical water treatment.

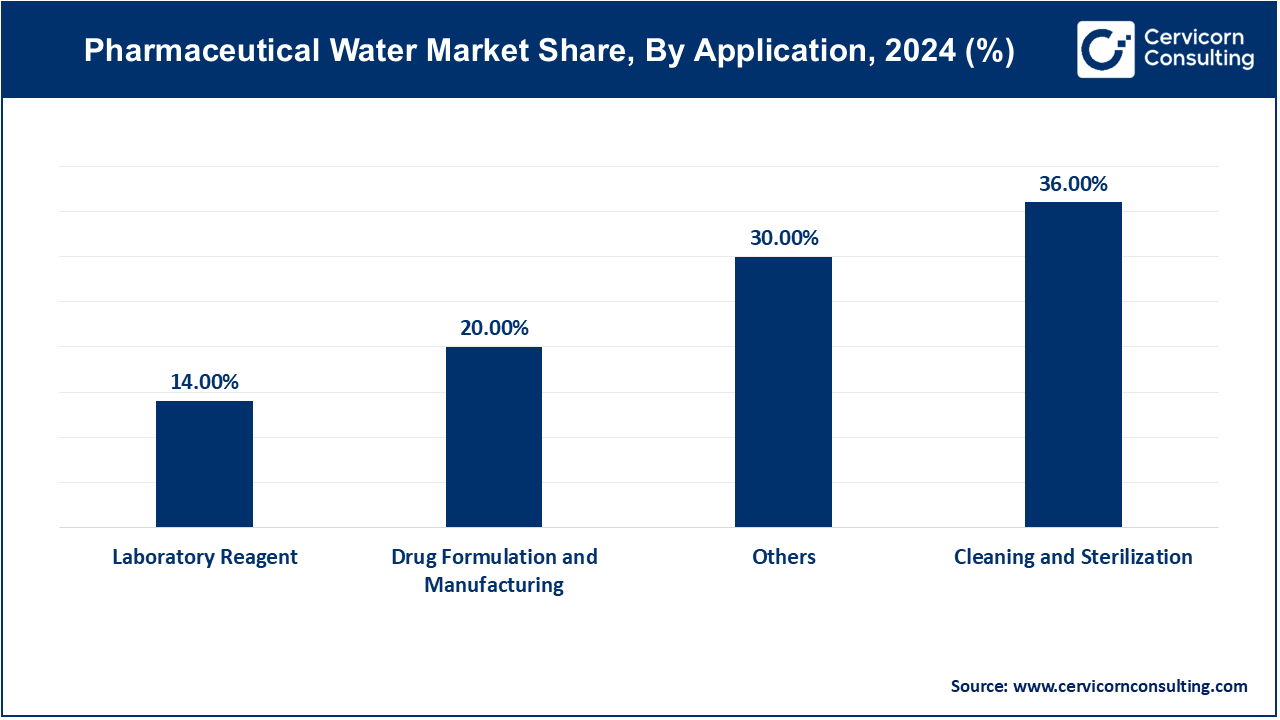

Drug Formulation and Manufacturing: Drug formulation and manufacturing segment has registered market share of 20% in 2025. Pharmaceutical water is essential in drug formulation and manufacturing processes, ensuring purity and safety of medications. Trends include increasing demand for high-quality water for biopharmaceutical production and stringent regulatory compliance.

Laboratory Reagent: Laboratory reagent segment has recorded market share of 14% in 2025. High-purity water is critical for accurate laboratory testing and research. Trends focus on advanced water purification technologies to meet precise laboratory requirements and enhance research reliability.

Cleaning and Sterilization: The cleaning and sterilization segment has garnered 36% of share in 2025. Water is vital for equipment cleaning and sterilization in pharmaceutical facilities. Trends emphasize efficient water treatment systems to maintain hygienic standards and reduce environmental impact.

Others: The other segment has accounted market share of 30% in 2025. This segment may include uses like HVAC system maintenance and environmental monitoring, where water quality plays a crucial role in supporting overall pharmaceutical operations and compliance.

Innovative newcomers in the pharmaceutical water market, such as BioPure Technology and PureAire Monitoring Systems, are leveraging advanced technologies like nanofiltration and real-time monitoring for water quality assurance. These companies focus on offering scalable, cost-effective solutions tailored to pharmaceutical manufacturing needs, driving market disruption. Key players dominating the market include Veolia Water Technologies, SUEZ Water Technologies & Solutions, and Merck KGaA. They lead through extensive global reach, comprehensive service offerings, and continuous innovation in water purification technologies. Their established reputations and robust regulatory compliance frameworks solidify their market leadership positions.

By Type

By Technology

By Application

By Regions