PEM Electrolyzer Market Size and Growth 2025 to 2034

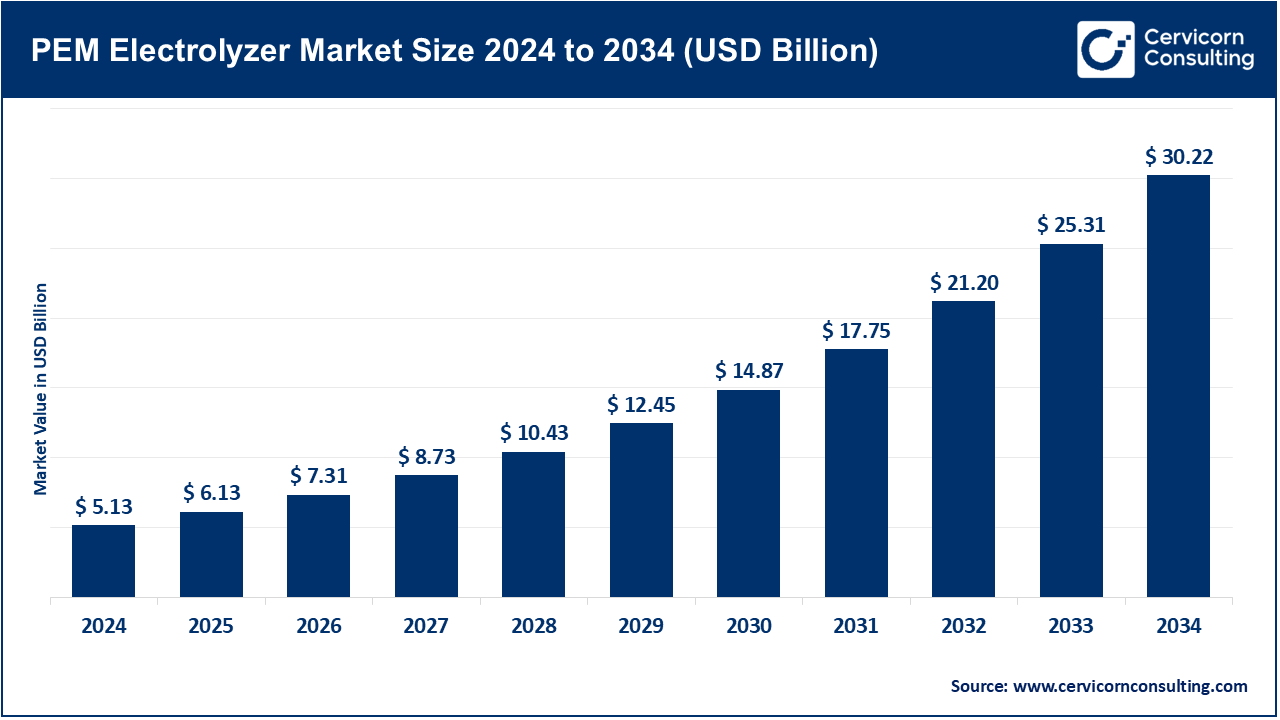

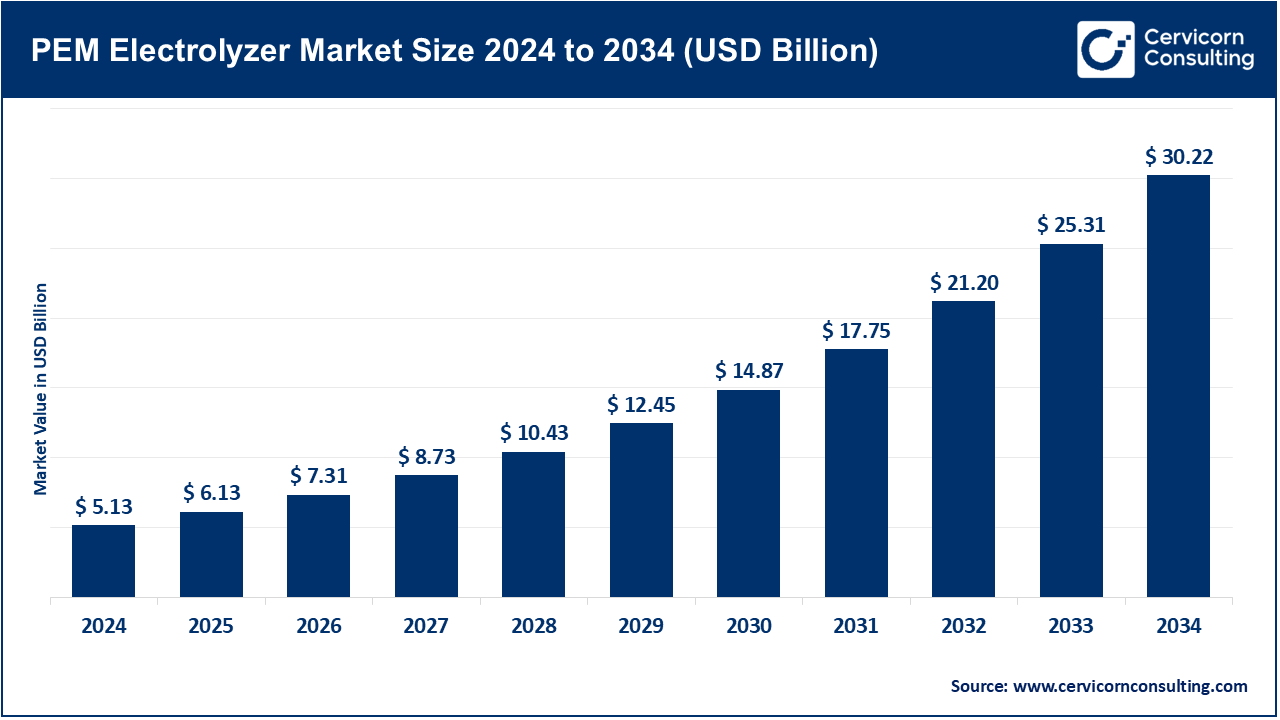

The global PEM electrolyzer market size was reached at USD 5.13 billion in 2024 and is expected to be worth around USD 30.22 billion by 2034, growing at a compound annual growth rate (CAGR) of 19.40% over the forecast period from 2025 to 2034.

The PEM (Proton Exchange Membrane) electrolyzer market is driven by the accelerating global energy transition. Countries are now formulating comprehensive hydrogen roadmaps supported by financial incentives, such as the US’s Inflation Reduction Act and the auctions under the EU Green Deal, which aim to decarbonise, enhance industrial competitiveness, increase resilience, and achieve energy self-sufficiency. At the same time, advancements in electrolyzer technologies designed to reduce reliance on precious catalysts, such as iridium, increase system lifespan, improve efficiency, and declining renewable energy prices are lowering the levelized cost of green hydrogen. All of these factors create an optimal economic environment for expanding the use of PEM electrolyzers in fuel cell electric vehicles, industrial feedstock, and power-to-gas energy storage.

Moreover, the growing need for clean hydrogen is accelerating the PEM electrolyzer market growth. High-purity hydrogen is crucial for fuel-cell electric vehicles (FCEVs) and the expanding hydrogen refueling network, making PEM electrolyzers vital. Additionally, heavy industries such as steel, chemicals, ammonia, and refining are increasingly seeking to use hydrogen to replace fossil fuels and are utilizing PEM systems to produce green hydrogen and green ammonia. Furthermore, the flexible operation of PEM electrolyzers can aid in grid services by either absorbing excess renewable power or providing frequency balancing, thus generating ancillary revenue and enhancing grid stability.

The global green Hydrogen production market is on the rise as a result of shifting strategies for emission reduction and the adoption of new renewable technologies. The Proton Exchange Membrane electrolyzer which has the ability to rapidly respond to power changing availability from wind and solar, is preferred due to its ease of use and compact design Moreover, these systems supply high-purity hydrogen critical for transport, industrial applications, and energy storage.

Corporative and governmental bodies are massively investing financially towards scaling production of green electolyzers due to the carbon neutrality target policies and funds incentives. Recently, research has focused on catalysts, membranes, and system integration which increase efficiencies while decreasing costs. As the hydrogen economy advances, strategic collaborations between energy corporations, researchers, and other electrolyzer manufacturers are becoming more normal while these systems emerge as a core technology aimed for a low carbon sustainable energy system.

Report Highlights

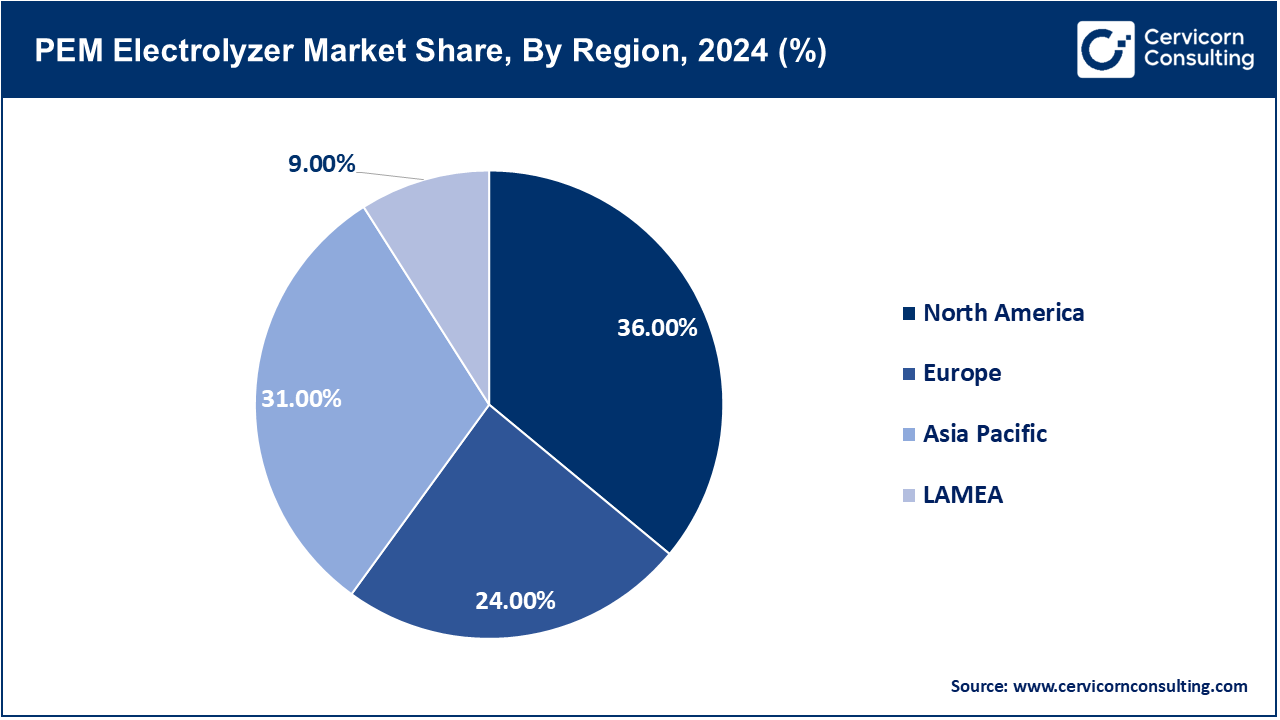

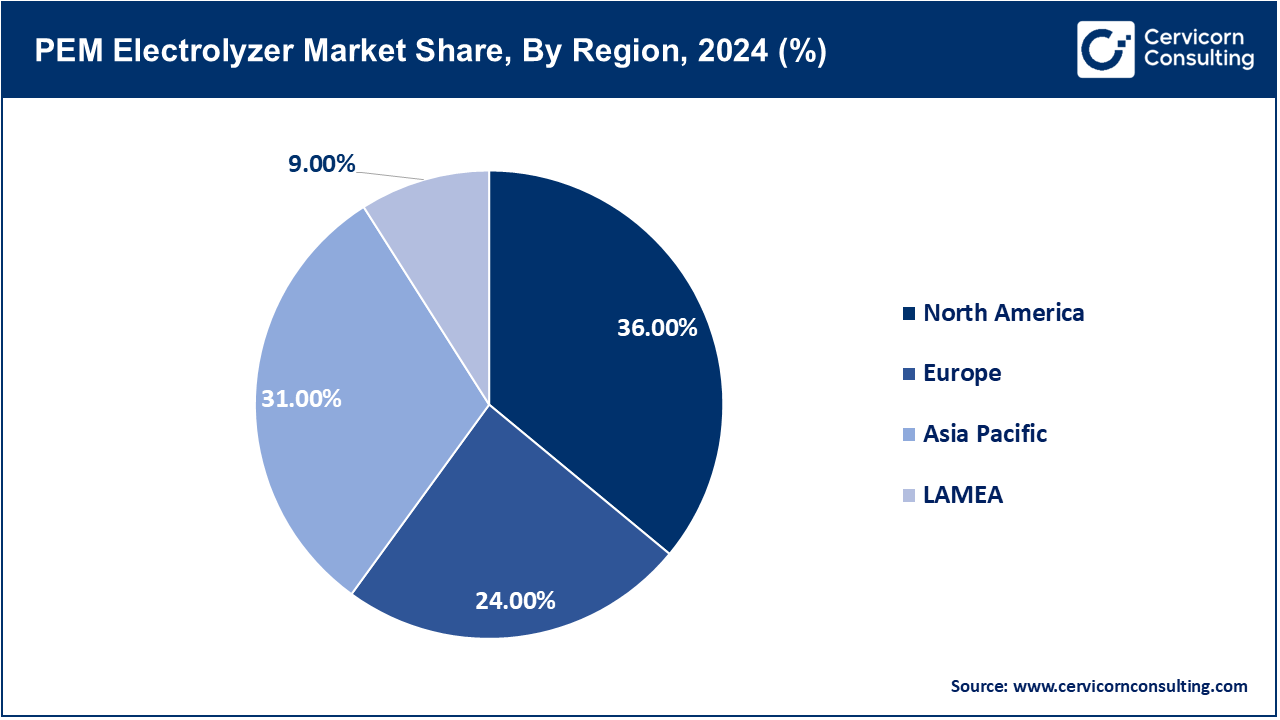

- By Region, North America accounted for a revenue share of 36% in 2024.

- By Region, Asia Pacific accounted for a revenue share of 31% in 2024.

- By Capacity, the above 2 MW segment recorded highest revenue share in 2024.

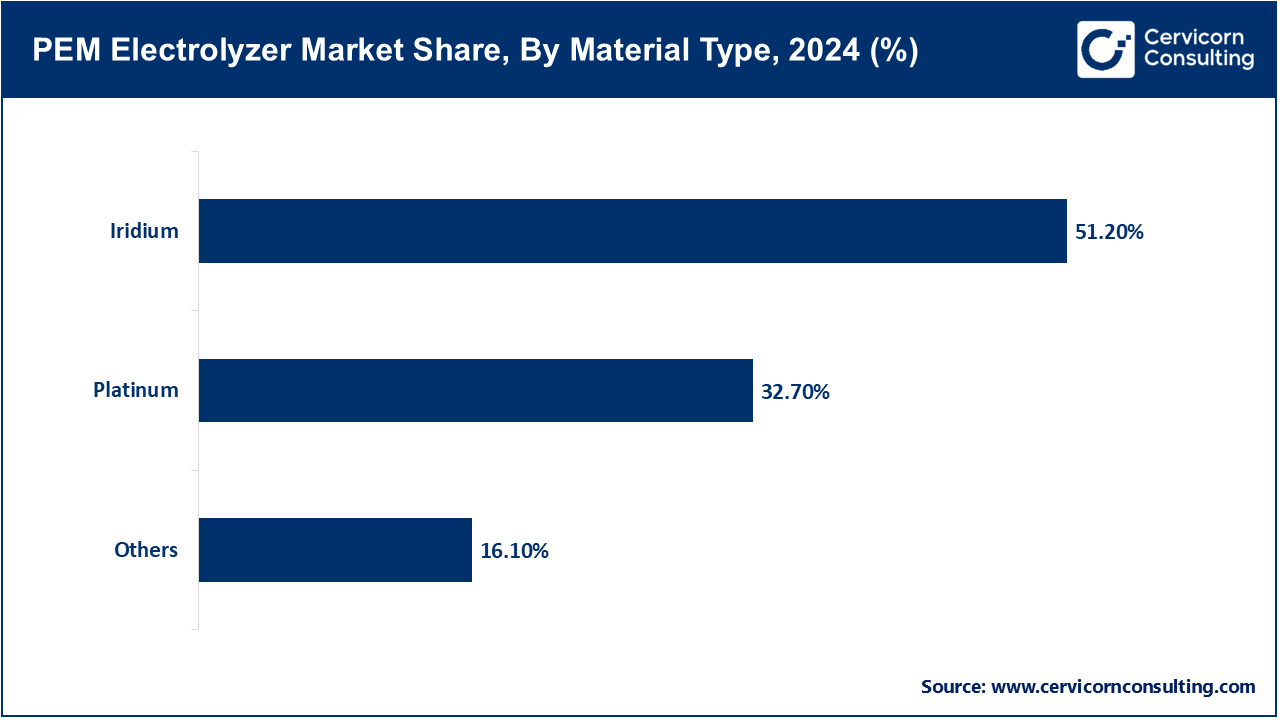

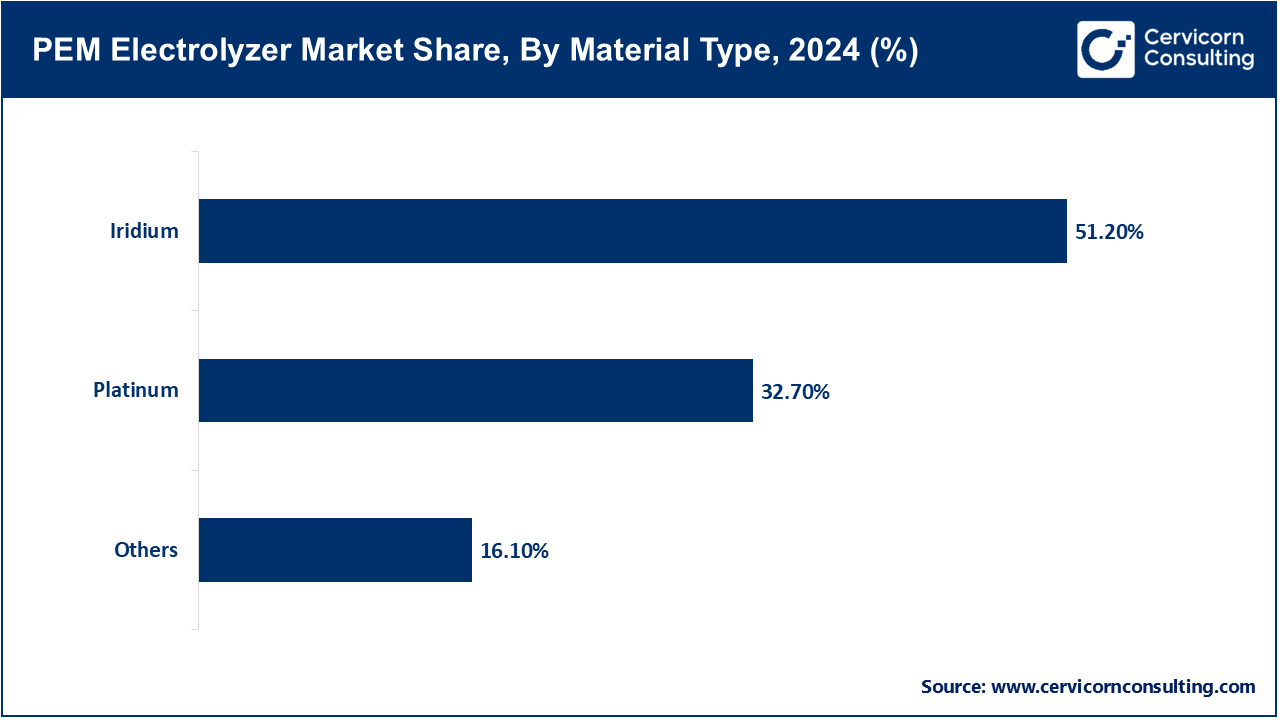

- By Material Type, the iridium segment has captured revenue share of 51.20% in 2024.

- By Application, the transportation segment has reported revenue share of 65.90% in 2024.

What are the PEM Electrolyzer Market Growth Factors?

- Rising Global Hydrogen Demand: Global hydrogen production reached around 87 Mt in 2023, yet clean hydrogen still comprises less than 1% of that total. Within the EU, mandates under the Renewable Energy Directive target 42% renewable hydrogen use in industry by 2030. In support of these initiatives, the European Hydrogen Bank announced in 2023 that it would spend more than USD 1.36 billion on renewable hydrogen projects. Furthermore, the US Department of Energy (DOE) is planning to subsidize electrolyzer hydrogen production, targeting a cost of $2/kg by 2026. India’s recently introduced Green Hydrogen Mission includes plans to incentivize the production of 5 Mt of green hydrogen by 2030 with credits amounting to INR 17,500 crore (~US$2.2 billion). These initiatives from different countries point to a strong positive shift in demand and available geopolitical support, rapidly boosting these projects, including PEM electrolyzer venture deployments.

- Government Incentives & Subsidies: According to the roadmap by U.S. DOE, between the years of 2022 to 2026 they expect costs of manufactured PEM stacks to reduce to $250/kW and bring hydrogen production down to $2/kg, with further reductions to to $1/kg by 2031. Under the U.S. According to the Inflation Reduction Act, tax credits of up to $3/kg may be awarded to clean hydrogen producers. In Europe, the European Hydrogen Bank offered USD 1.36 billion in the second 2025 auction for financial support of renewable hydrogen projects. In April 2025, Spain also received USD 0.4 billion in state aid for green hydrogen under the “auction-as-a-service” funding scheme. These strong subsidies are diminishing the risk and increasing the return potential of investments, thus greatly accelerating the adoption of the PEM electrolyzer market.

- Increased Renewable Energy Adoption: As of late 2023, renewable constituted 42.5% of the EU’s total energy consumption while renewable heating and cooling accounted for 26.2%. In order to meet the DOE goals of 2026 for hydrogen production cost of $2/kg, culvert UISD 34.2/MWh for renewable power is imperatives. Under the REPowerEU program, the EU initiated “Hydrogen Valleys” in March 2023, which aims to combine renewable electricity with electrolyzers. A 2024 study pointed out that that there are up to 10% savings in costs with hybrid renewable powered PEM systems over standalone setups. The increasing availability of renewables is improving the economics and deployment of PEM electrolyzers.

What are the PEM Electrolyzer Market Trends?

- Hybrid Systems (Solar, Wind + PEM): In 2023, the European Union funded programs relating to the “Hydrogen Valleys” which included the addition of wind and solar power along with PEM electrolyzers at regional concentrator hubs. An academic dissertation in 2024 claimed that merging PEM with direct air capture systems would improve the economic efficiency of hydrogen production by nearly 10% compared to stand-alone systems. Pilot programs in Denmark have shown that operational flexibility can increase revenue by approximately 57% via ancillary service revenues to the grid. This blend improves renewables asset utilization, helps stablish the grid, and ALIGNS with EU carbon reduction policies. The increased public and private investment spurred as a result of practical success is noteworthy.

- Modular, Decentralized PEM Units: Bosch announced the launch of “Hybrion,” a containerized modular PEM electrolyzer with two 1.25 MW units, for early 2025. It incurred 100 MW worth of global orders during its development. These systems are versatile because they can be deployed in industrial parks, maritime ports, and other remote locations, minimizing hydrogen transport. These policies receive backing from programs established by the EU Hydrogen Bank. The REPowerEU policy changes slated for 2023–2025 expedited the permitting process for modular electrolyzers cultivsited to bolster local hydrogen generation, enhancing a region’s energy resilience.

- AI & IoT for PEM Optimization: The target goals set forth by the Department of Energy for 2026 indicate overhauling monitoring and control systems will be essential if the goal of reducing PEM degradation rate from 4.8 mV to 2.3 mV per 1000 hours is to be achieved. The 2024 assessment report “Hydrogen Shot” published by DDOE stated that lifetime hydrogen costs identified with AI and analytics was near $6.6/kg to $4.5/kg. As part of MyPP pilot programs, the DOE has IoT-enabled diagnostics and dynamic control systems for PEM plants being deployed through May 2024. These outcomes are hetter aligned with DOE cost objectives and enable enhanced stack longevity and reduced PEM maintenance, thus facilitating more sophisticated and dependable PEM operations.

Report Scope

| Area of Focus |

Details |

| Market Size in 2025 |

USD 6.13 Billion |

| Expected Market Size in 2034 |

USD 30.22 Billion |

| Projected Market CAGR 2025 to 2034 |

19.40% |

| Top-ranking Region |

North America |

| High-growth Region |

Asia-Pacific |

| Key Segments |

Capacity, Material Type, Application, Region |

| Key Companies |

Air Liquide, Air Products and Chemicals, Inc., Cummins Inc., Erre Due s.p.a., Elogen, Giner, ITM Power, LARSEN & TOUBRO LIMITED, Nel ASA, ostermeier H2ydrogen Solutions GmbH, Plug Power, Siemens Energy |

PEM Electrolyzer Market Dynamics

Market Drivers

- Electric Vehicle & FCEV Expansion: Hydrogen-powered trains are receiving €9 billion in funding from Germany as part of its 2023 Hydrogen Strategy. Additionally, South Korea plans to have 30,000 hydrogen trucks by 2030. EU policies, strengthened with the launch of the Carbon Border Adjustment Mechanism in October 2023, require the usage of low carbon hydrogen in transport. The U.S. also subsidizes spending on clean fuels through the IRA, offering tax credits for clean hydrogen production intended for heavy vehicle engines. These new policies and the increasing climate change mitigation efforts in the transport sector drive the need for high-purity PEM hydrogen, which brings further investment in production facilities and development of fuel infrastructure.

- Energy Security & Localization: Finland government targets adding 2.2 Gigavatts electrolyzer capacity which includes one gigawatt of PEM for ammonia production and renewable energy pipelines by 2030. India’s Green Hydrogen Mission 2023 seeks to promote the production of hydrogen in the country by eliminating electricity transmission fees and subsidizing manufacturing in order to lessen the reliance on imported coal. EU-funded The Hydrogen Bank further stimulates the regional green hydrogen supply industry with auctions in April 2025. These policies aim at increasing resiliency while deepening reliance on economically bounded energy geopolitics, securing continental energy independence, and framing broader military objectives.

- Catalyst Efficiency & Cost Reductions: The DOE roadmap of 2026 expects to lower capital expenditures by reducing PGM catalyst loading from 0.8 g/kW to 0.1 g/kW. A report by the DOE in 2024 “Hydrogen Shot” focused on innovations towards achieving better than 80% PEM stack efficiency. The report suggested that this level is required to meet the $1/kg hydrogen target. Ongoing research and development by DOE and EU Innovation Fund programs (2023-2024) aim at lessening the dependence on iridium and increasing stack durability. These developments are essential for advancing the cost efficiency and sustainability of PEM electrolyzers.

Market Restraints

- Raw Material Scarcity: By 2023, over 80% of iridium and 91% of platinum reserves were located in South Africa, and around 30% of titanium sponge production relied on Russia. A single 1 GW PEM installation may require 500 kg of iridium—nearly 15% of global production. The limited supply and PGMs’ increasing demand are likely to cause price surges and market bottlenecks. In regard to these challenges, the 2024 Hydrogen Shot initiative from DOE and EU research grants have concentrated on developing alternative catalytic materials to lessen these strategic dependencies.

- Infrastructure Gaps: The DOE has set a target of $2/kg Hâ‚‚ by 2026, given over 90% electrolyzer uptime and strong downstream infrastructure, while also assuming upstream infrastructure objectives are achieved. There is an electrolyzer downstream, beyond it, there is only limited hydrogen pipeline networks, storage, and refueling stations constituting the downstream infrastructure. The EU plans to extend a pan-European hydrogen backbone by 2030 under REPowerEU, with full realization not occurring until the mid-2035. There are pilot programs such as the EU Hydrogen Bank matchmaking service attempting to streamline infrastructural plans. However, participants are still working through significant logistical and cost hurdles without adequate built-out support.

Market Opportunities

- Decarbonization Drive: Attaining globally recognized milestones, carbon neutrality drives the need for hydrogen as a more efficient energy source. Solar or wind energies aid the generation of green hydrogen, thus making PEM electrolyzers pivotal in the clean hydrogen economy. Their discharge dynamics allow for rapid production escalation and de-escalation which furthers their importance for intermittently renewable sources. Consequently, making them pivotal to future low-carbon industrial and energy systems world-wide.

- Fuel Cell Vehicle Adoption: The commercial market potential for fuel cell electric vehicles (FCEVs) is rapidly increasing, thus augmenting the need for hydrogen production framework, particularly in commercial transport. This demand is effectively met with PEM electrolyzers since they can supply high quantities of ultraclean hydrogen needed for these vehicles. Hydrogen refueling stations are being constructed by governments and private companies which is enhanced by subsidy schemes and investment policies advocating for clean transport. Such a trend promote the goals of sustainable emission-free transport while providing lucrative growth for PEM manufacturers and system integrators within the mobility market.

- Second-Life Battery Integration: The new synergies developing between PEM electrolyzers and second life batteries present a comprehensive approach to energy storage. Batteries from electric vehicles can be used as stationary storage for electrolyzers, helping to level energy supply fluctuations. This integration permits uninterrupted operation, enhances energy efficiency, and increases the value of spent batteries which contributes towards circular economy. It serves as an incentive for innovative solutions within microgrids, off grid hydrogen production, and distributed energy systems.

Market Challenges

- High Capital Expenditure: The PEM electrolyzer market’s most immediate and important issue is concern is lack of systems. Presently dipped the precision of strategically placed ion is systems for PEM electrolyzers remain subjected to major barriers such as schemed precision placed. Each of these systems encompasses financial and manual expenditure costing ranging from $1,000 to $1,800 per kilowatt. Such a huge driver focuses systems on advanced components based on manufacturing, complexity, and the need of hard metals. From the perspective of mid to small enterprises, this exhibiting advanced sectors is unviable until great strains of subsidies are present.

- Raw-Material Scarcity: PEM based electrolyzers relay heavily acquire platinum and peculiar materials jerk iridium, in the form of their inter playing coaxial layers of catalysts. These supply surroundings along the peak concentrate because of geopolitics why focus central to a particular area of mining leads to questions about it to build and stable in low costs containing price of businesses. Supply scope along with dire changing and strangling capabilities suddenly without components in amino terms lack of sustained struggle greatly.

PEM Electrolyzer Market Regional Analysis

The PEM electrolyzer market is segmented into several key regions: North America, Europe, Asia-Pacific, and LAMEA (Latin America, Middle East, and Africa). Here’s an in-depth look at each region

Why North America region dominated the PEM electrolyzer market?

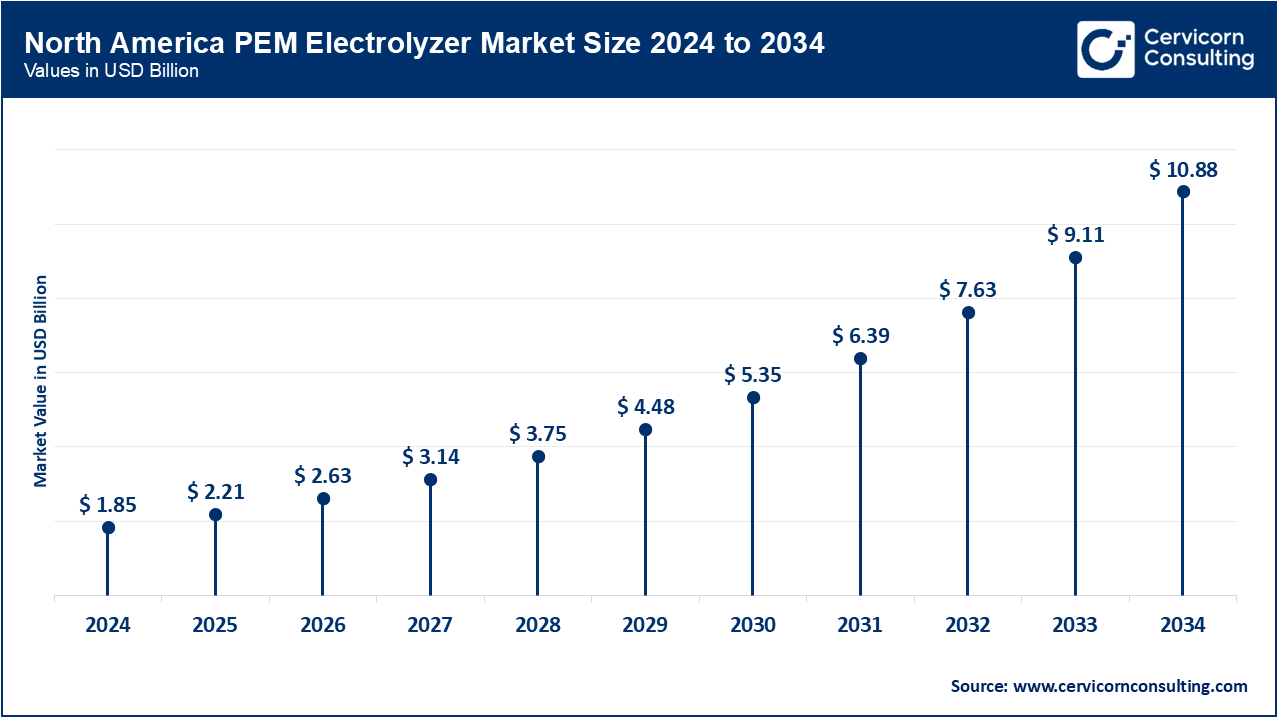

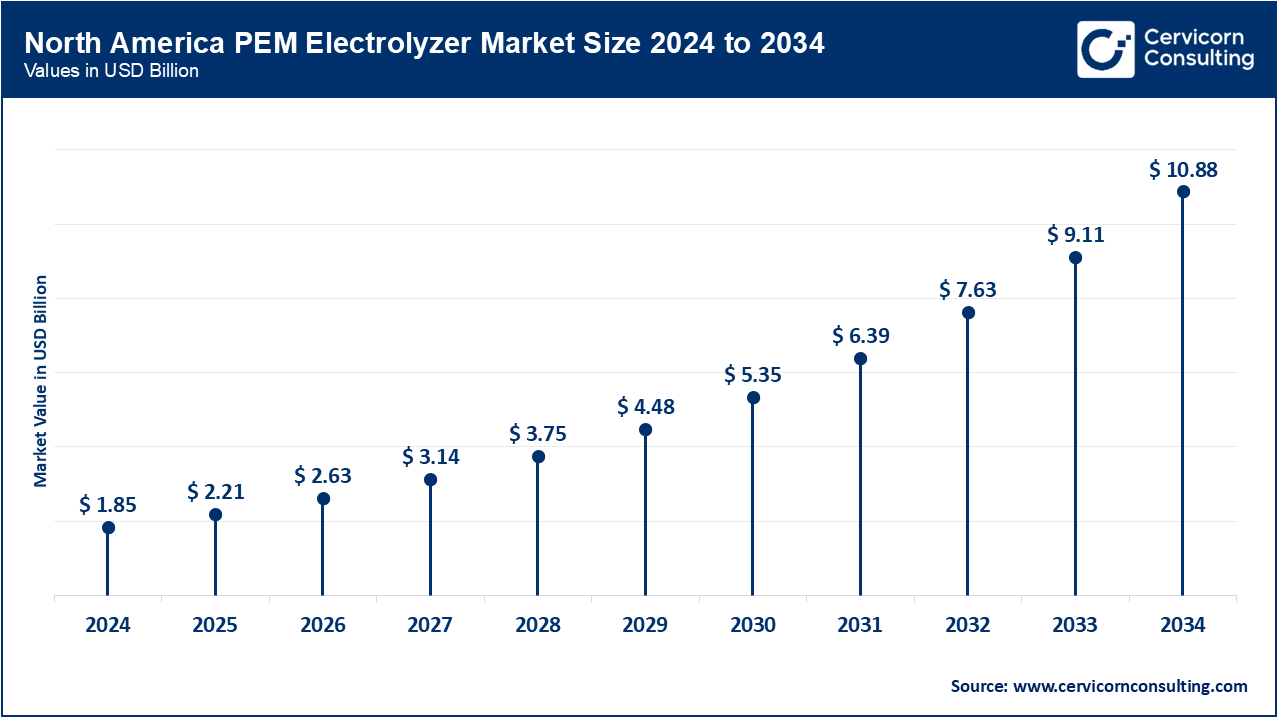

- North America Market Size in 2024: USD 1.85 Billion

- North America Expected Market Size in 2034: USD 10.88 Billion

In September 2024 the DOE awarded roll-to-roll manufacturing innovation USD 0.008 billion to scale PEM electrolyzers and fuel cells in America. Canada’s Clean Fuels Fund Of 2021 (CAD 1.5 billion) is now funding green electrolyzers for electrical and industrial use with pilot projects being executed in Alberta. Mexico is assessing hydrogen-to-power demonstrations as part of the national clean energy strategy integrated with CFE’s studies done post-2023. North America-wide, policies like the US IRA tax credits and Canada’s federal promotion are aggressively incentivizing implementation and PEM manufacturing. All these actions signal heightened momentum toward hydrogen resilience and industrial decarbonization.

Europe PEM Electrolyzer Market Trends

- Europe Market Size in 2024: USD 1.23 Billion

- Europe Expected Market Size in 2034: USD 7.25 Billion

Europe’s REPowerEU strategy of 2023 allocated 10 Mt of renewable hydrogen by 2030 along with supporting electrolyzer deployment through the European Hydrogen Bank. Germany’s funding in 2023 of BASF’s 54 MW PEM electrolyzer with USD 0.14 billion government aid marks one of Europe’s largest PEM projects. UK proposed spending USD 2.7 billion on a green hydrogen fund which includes trials of membrane-based electrolyzers powered by wind offshore in December 2023. France aims for 6.5 GW of electrolyser capacity by 2030 as part of their hydrogen roadmap and already has HYVIA’s Flins plant which produced PEM fuel cells and electrolyzers in 2022 so, is able to self-supply. The acceleration of integrated industrial hydrogen systems throughout Europe is remarkable.

Why is Asia-Pacific fastest growing region in PEM electrolyzer market?

- Asia-Pacific Market Size in 2024: USD 1.59 Billion

- Asia-Pacific Expected Market Size in 2034: USD 9.37 Billion

China’s electrolyzer capacity stood at 1.2 GW by the end of 2023, accounting for nearly fifty percent of the global total. This was supported by the 2021-2035 hydrogen plan and provincial subsidies. India implemented its National Green Hydrogen Mission in January 2023 allocating funds of INR 17,490 crore (~USD 2.4 billion) for 5 Mt production and 1.5 GW electrolyzer tenders through SIGHT. Japan’s revised Basic Hydrogen Strategy for June 2023 plans to disburse JPY 15 trillion (approximately USD 100 billion) by 2038 with an aim to supply 3 Mt hydrogen by 2030 while commencing 10 MW PEM Fukushima renewable electrolysis plants. Through ARENA, Australia funded USD 0.04 billion up until 2020 and approved a 200 MW plant in Whyalla in November 2024. In 2024 South Korea completed construction of H2 pipelines in Ulsan as well as 188 kilometers of H2 Green Hydrogen Town backbone infrastructure.

LAMEA PEM Electrolyzer Market Trends

- LAMEA Market Size in 2024: USD 0.46 Billion

- LAMEA Expected Market Size in 2034: USD 2.72 Billion

Brazil initiated the National Green Hydrogen Program in 2023, which expects to pilot PEM electrolyzers alongside wind-solar farms in the northeast region. In the UAE, COP28 Dubai Declaration (Dec 2023) approved reciprocal certification systems aimed at low-carbon hydrogen exchange. Saudi Arabia in early 2024 awarded projects under its Vision 2030 framework which incorporated PEM-backed green ammonia plants at NEOM, backed by sovereign wealth funding. South Africa’s Department of Mineral Resources and Energy progressed with the draft plans 2024 concerning hydrogen economy strategies centered around PEM Electrolyzers for the establishing of platinum group catalysts. These projects highlight growing concern with regard to hydrogen as an energy export and as a resource for industrial transformation for the region.

PEM Electrolyzer Market Segmental Analysis

Capacity Analysis

≤ 500 Kw: Small PEM electrolyzers (≤500 kW) are well suited for remote power and industrial pilot sites. In 2023, Europe’s small electrolyzer market was approximately valued at US$ 0.124 billion, where PEM units over 60% of the installations in the ≤500 kW range. It is also notable that in May 2024, SECI of India was awarded tenders for electrolyzers, including sub-500 kW units, under the SIGHT program for 295 MW. North America commissioned a 1 MW PEM electrolyzer at Amazon’s Colorado fulfillment center in Jan 2024 for forklift fueling. These compact units are also supported by policy incentives, like the U.S. IRA, which are vital for rural electrication and spearhead hydrogen pilot hubs. Advancements in durability of stacks and modular design make these more feasible. government-backed tenders and projects are increasingly relevant in these local hydrogen ecosystems.

> 500 kW – 2 MW: Mid-scale PEM electrolyzers (0.5–2 MW) serve industrial parks, ports, and refueling stations. India’s 2024 electrolyzer tender under SIGHT included units up to 2 MW, with 23 companies bidding over 2.8 GW cumulative capacity. In the U.S., Plug Power commissioned a 1 MW PEM electrolyzer in Colorado for supplying hydrogen to over 225 fuel-cell forklifts. Europe’s Hydrogen Valleys pilot projects integrate these mid-sized units with wind and solar, supported by EU Innovation Fund and REPowerEU grants. These systems balance scalability and flexibility, meeting both on-site generation and grid support roles. Permitting reforms in EU countries (2023-2025) further enable deployment. Their prevalence in transportation and industry signals growing adoption in hydrogen demand zones.

Above 2 MW: Large-scale (> 2 MW) PEM electrolyzers are well-suited for utility-scale integration and industrial decarbonization. Siemens/EWE issued plans for a 280 MW PEM plant in Emden, Germany, with projected commissioning in 2027, receiving USD 5.2 billion EU funding under IPCEI. Europe’s global electrolyzer pipeline is expanding, however, Reuters highlights only 12% have reached FID, and projection suggests undershooting EU targets. North American project pace continues to lag, aside from notable efforts such as Canada's Coyote Hâ‚‚. The US IRA tax credit appears poised to incentivize commercial-scale installs. Green steel and other chemicals and large power-to-X systems depend critically on these systems. Their deployment emphasizes the shift towards scale of clean hydrogen.

Application Analysis

Power Generation: The electrolyzers are undergoing wider utilization in seasonal and grid balancing storage. In Europe, the Hydrogen Valley pilots funded by REPower EU are showcasing integrated storage-support hybrid systems. These systems are projected to reduce LCOH by 10% in comparison to electrolysis done independently, according to the DOE estimates. Focusing on the North American side, there is an interest in using hydrogen as a backup for grids with higher renewables share. Other examples are the Emden PEM projects aimed at COâ‚‚ reduction in the power sector. Construction and regulatory frameworks from US and EU strategies on energy transition further strengthen hydrogen’s role as a flexible generation asset.

Transportation: Hydrogen mobility fuels buses, trucks, and trains thus increasing the demand for PEM electrolyzers. The German Hydrogen Strategy of 2023 allocated USD 10.2 billion to train decarbonization and fueling infrastructure expansion. South Korea has a goal of 30,000 Hâ‚‚ trucks by 2030. In Colorado, Plug Power has a 1 MW electrolyzer that services fuel-cell forklifts and India has a 2024 tender that features transport specific devices. Spain’s Hympulso initiative and California’s SoHyCal facility are expected to advance hydrogen fueling pilots in 2024. These regionally directed projects strengthen policymakers’ goals for transport.

Industry Energy: Companies like data centers and glass and cement production are looking into onsite hydrogen power generation. In Europe, hydrogen is proposed for industrial energy use under REPowerEU targets, and pilot plants are already in construction. In North America, mid-scale PEM units are already in use in Clean Power Generation Integrated Industrial Parks. U.S. government grants and pilot programs, like_ Hydrogen Shot_ by the DOE, aim to minimize fossil gas dependence in industrial applications. Industrial users become interested in captive hydrogen generation as electrolyzer costs drop due to gas-less energy resilience and improving reliability.

Industry Feedstock: PEM hydrogen is increasingly used as feedstock by the refining and steel industries, ammonia and methanol production. The Siemens/EWE Emden plant will provide 26,000 t/year green hydrogen for industrial consumption. Low-carbon feedstock procurement becomes mandatory for EU member states with new CBAM obligations since October 2023. Finland's aim of a 1 GW PEM electrolyzer by 2030 includes support for ammonia production. There are global efforts to retrofit grey hydrogen plants with PEM stacks as stationary units which the US DOE and the EU support. These changes get additional justification from climate ambitions and financial incentives based on feedstock decarbonization.

Building Heating & Power: Hydrogen is emerging as a clean energy candidate for building-level heating and power in Europe. Demonstrators under REPowerEU include PEM electrolyzers paired with fuel cells for commercial buildings in Germany. DOE grants in 2024 are funding microgrid installations using PEM for emergency backup power. These systems are cleaner than diesel generators for sustaining emergency power in critical hospitals and services. Even though these systems are still in pilot testing, they are gaining supportive policy attention, especially for curtailing methane emissions from cities.

Material Type Analysis

Based on material type, the market is classified into iridium, platinum and others. The iridium segment dominated the market in 2024.

PEM Electrolyzer Market Top Companies

Recent Developments

Recent partnerships in the PEM electrolyzer industry emphasize innovation and clean energy collaboration. Siemens Energy and Air Liquide formed a joint venture in 2023 to industrialize PEM electrolyzer manufacturing in Germany, targeting 3 GW annual capacity by 2025. Cummins partnered with Tata Motors and Indian Oil Corporation under India’s National Green Hydrogen Mission to accelerate PEM deployment. Plug Power joined forces with Fortescue and Olin Corporation to establish large-scale PEM-based hydrogen production hubs in the U.S. ITM Power and Linde collaborated to deploy next-generation PEM systems for industrial decarbonization across Europe. Nel ASA partnered with Statkraft to deliver green hydrogen from PEM units for mobility and ammonia synthesis. These alliances are accelerating electrolyzer scaling, reducing cost, and integrating hydrogen into global energy systems.

- In February 2025, At Tata Passenger Electric Mobility (TPEML), a subsidiary of Tata Motors, has completed the acquisition of Ford India’s manufacturing plant in Sanand, Gujarat, for Rs 725.70 crore, including the entire land, buildings, vehicle manufacturing plant, machinery, and the transfer of eligible Ford India employees to TPEML as of January 10, 2023. This move adds an additional manufacturing capacity of 300,000 units per year, scalable to 420,000 units, supporting Tata Motors’ growth and investment plans in electric vehicles, as its existing capacities are nearing saturation. Following the announcement, Tata Motors’ shares rose by 6.07%.

- In May 2025, ITM Power has signed an agreement to supply over 300MW of its proton exchange membrane (PEM) electrolysers for a green hydrogen power plant in the Asia-Pacific region, with the customer remaining confidential at this stage. The project, which aims to use green hydrogen for power generation and reduce carbon emissions, has received funding approval from local authorities but is still subject to a final investment decision (FID). ITM Power’s CEO expressed enthusiasm for advancing the project’s engineering, permitting, and integration phases, highlighting the company’s capability in large-scale green hydrogen deployments.

Market Segmentation

By Capacity

- ≤ 500 kW

- > 500 kW – 2 MW

- Above 2 MW

By Material Type

By Application

- Power Generation

- Transportation

- Industry Energy

- Industry feedstock

- Building Heating & Power

By Region

- North America

- APAC

- Europe

- LAMEA