Artificial Intelligence (AI) in Chemicals Market Size and Growth 2025 To 2034

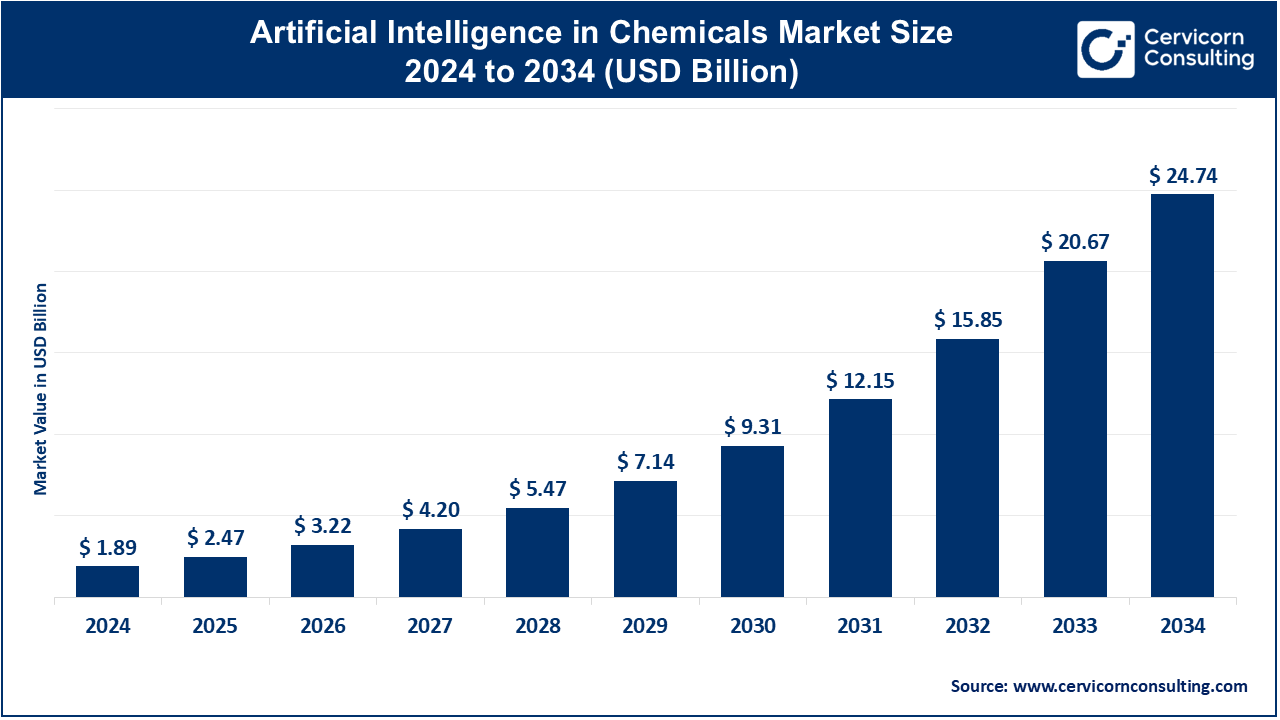

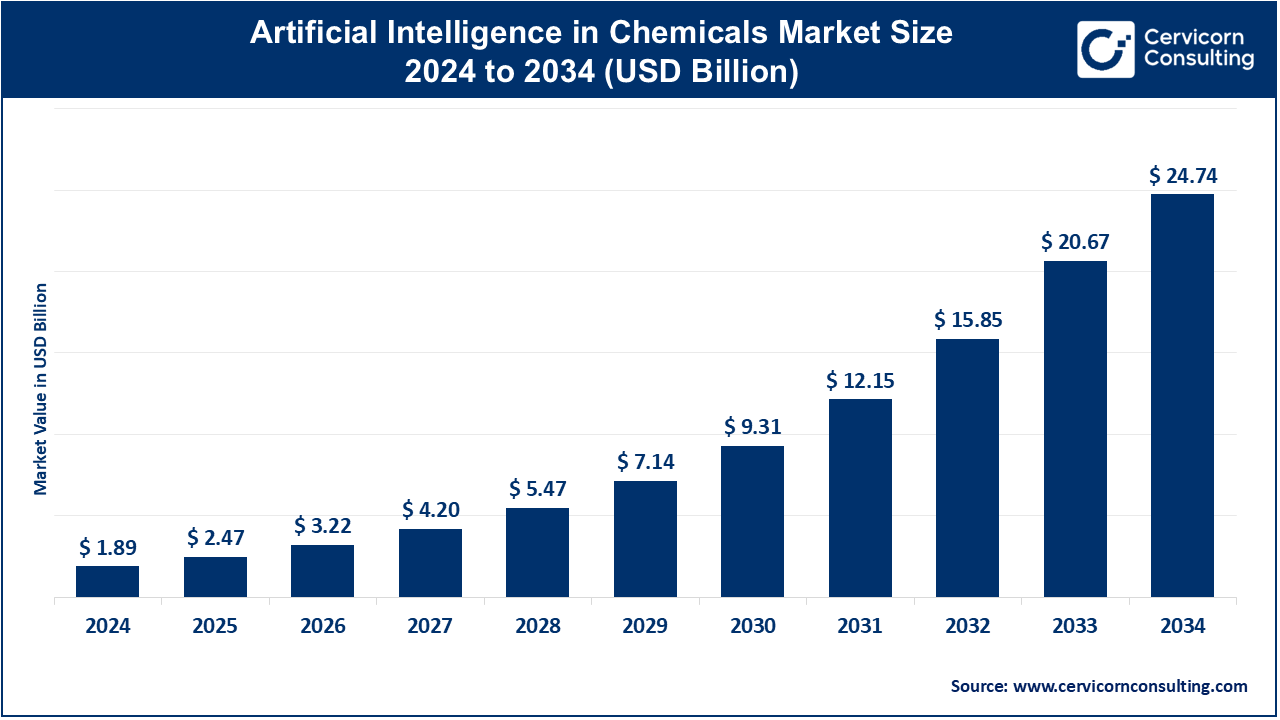

The global artificial intelligence (AI) in chemicals market size was accounted for USD 1.89 billion in 2024 and is expected to reach around USD 24.74 billion by 2034, growing at a compound annual growth rate (CAGR) of 29.33% over the forecast period 2025 to 2034.

The Artificial Intelligence (AI) in chemicals market is witnessing significant growth, driven by increasing demand for automation and efficiency within the industry. The adoption of AI technologies helps chemical companies reduce production costs, improve product quality, and optimize resource utilization. In particular, AI-powered tools assist in enhancing R&D capabilities, helping firms develop innovative products and solutions faster. The market for AI applications in the chemical industry is expanding rapidly due to the rising need for sustainable manufacturing practices and the shift towards digital transformation across industries. This growth is further fueled by investments from major chemical companies in AI-driven technologies, aiming to remain competitive in a rapidly evolving market. As AI continues to revolutionize chemical production and R&D, market forecasts suggest that the global market for AI in chemicals will experience substantial growth in the coming years.

Artificial Intelligence (AI) in chemicals refers to the application of AI technologies such as machine learning, data analytics, and optimization techniques to improve various processes in the chemical industry. AI in chemicals helps to streamline operations by enhancing research and development (R&D), accelerating chemical discovery, and optimizing production processes. By analyzing large sets of data, AI can identify patterns and predict chemical behaviors, aiding in the development of new materials, chemicals, and efficient production methods. It also plays a role in predictive maintenance, reducing equipment downtime, and increasing the safety and sustainability of operations. AI-powered tools are increasingly being used in chemical simulations, helping scientists and engineers predict reactions and optimize formulations.

- Robotic systems are employed by companies like Novartis to handle chemical compounds in multi-well plates, enabling continuous, 24/7 laboratory testing of products and substances, thereby expediting the drug discovery and development process.

- Firms such as Blue Yonder leverage AI and machine learning techniques to enhance forecasting, replenishment, and pricing adjustments.

- Pfizer utilizes data science, AI, and real-world data to create more precise treatment options and accelerate chemical study completions.

- According to Nature Communications, AI services enable organizations to achieve approximately 63% higher environmental sustainability.

Artificial Intelligence (AI) in Chemicals Market Report Highlights

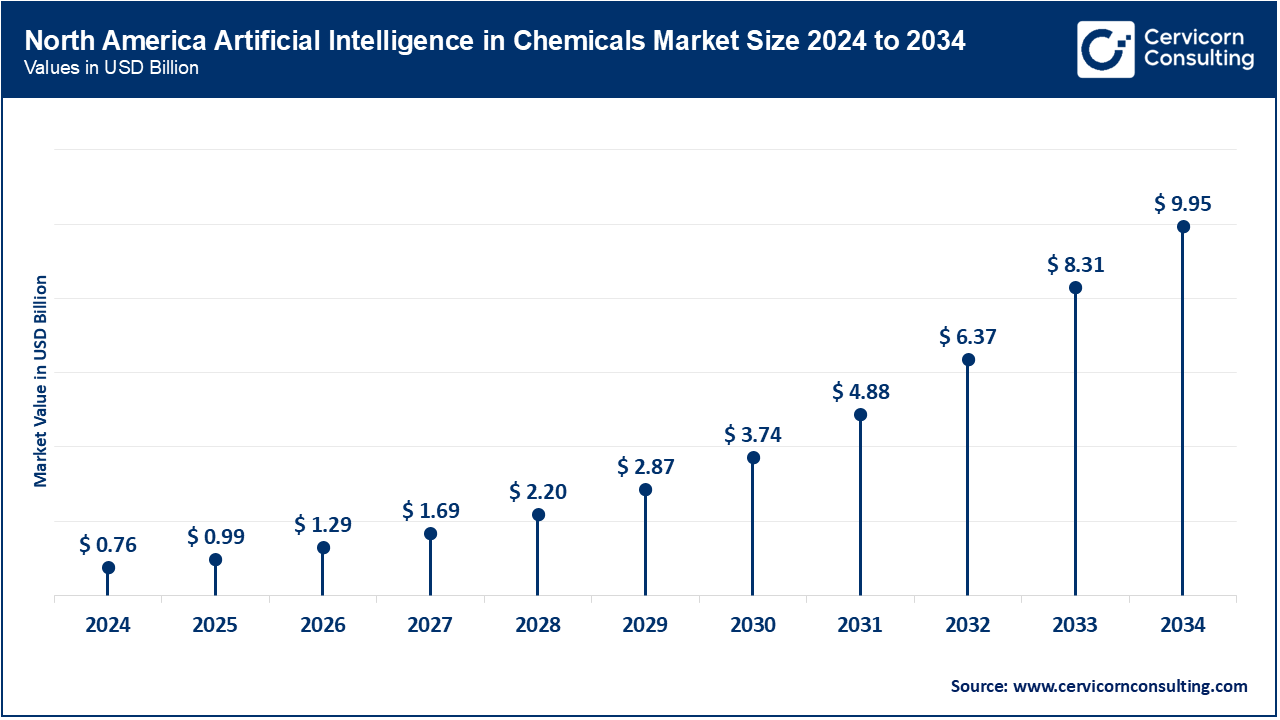

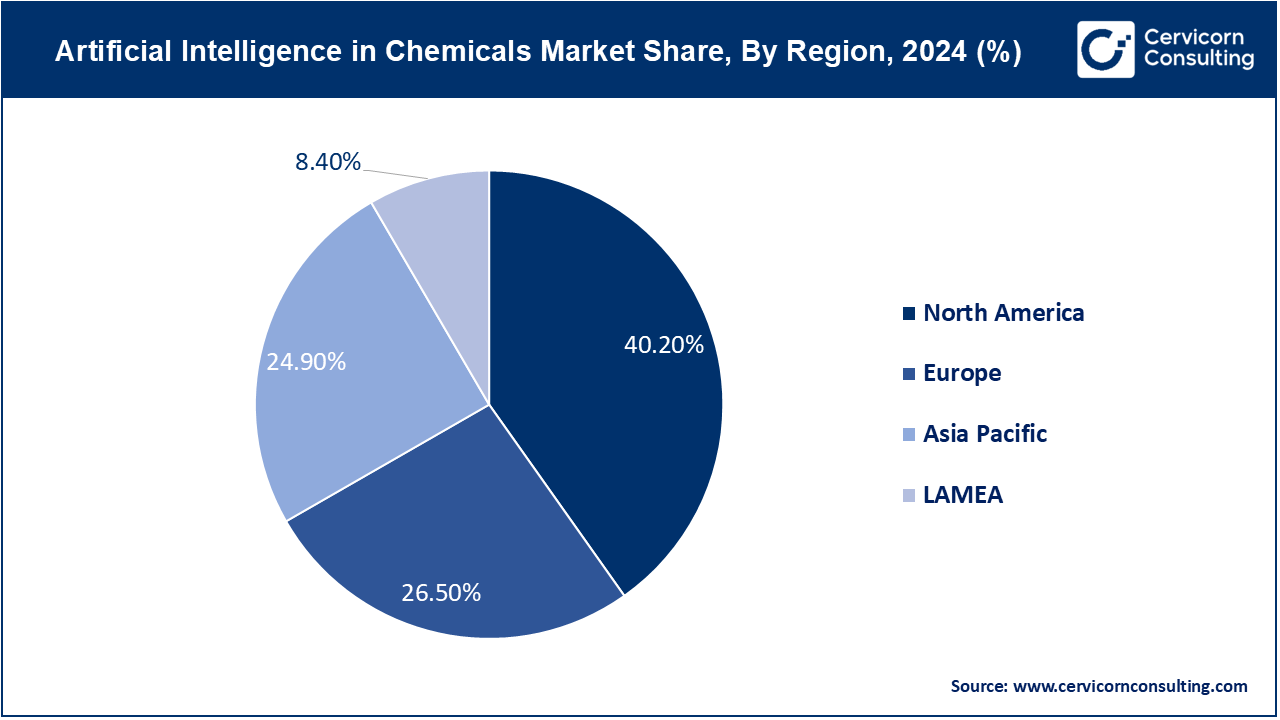

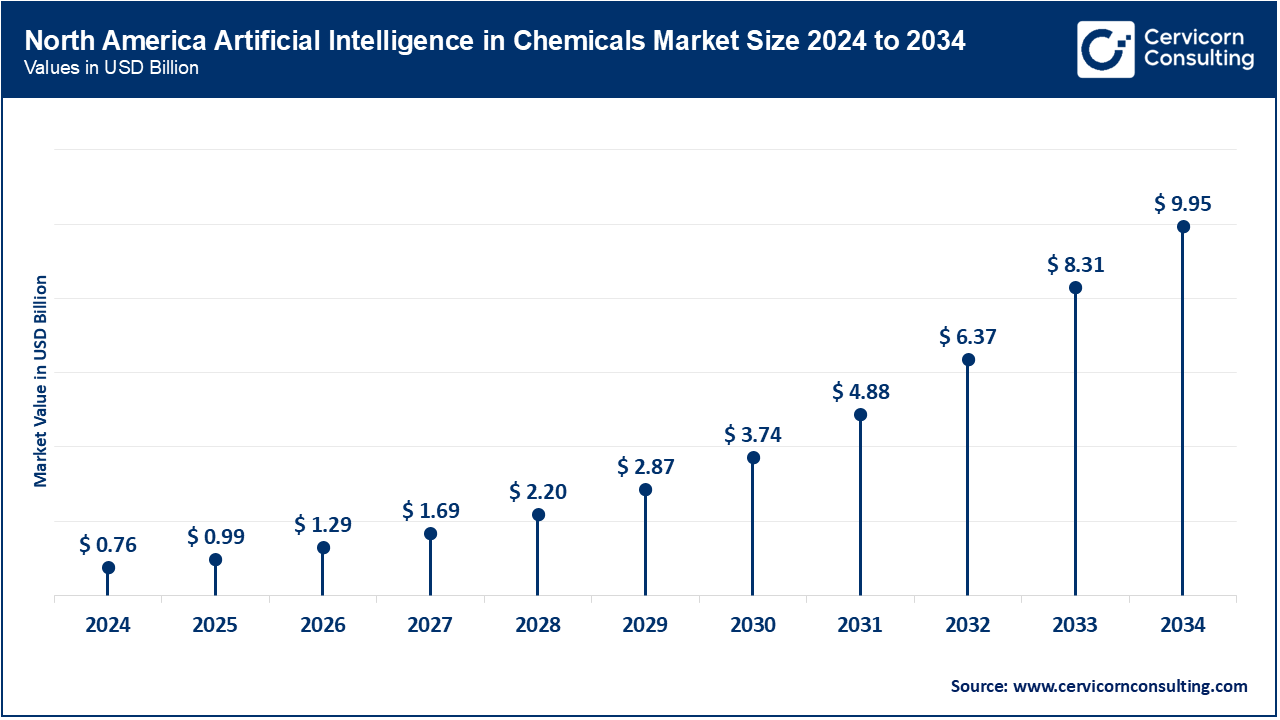

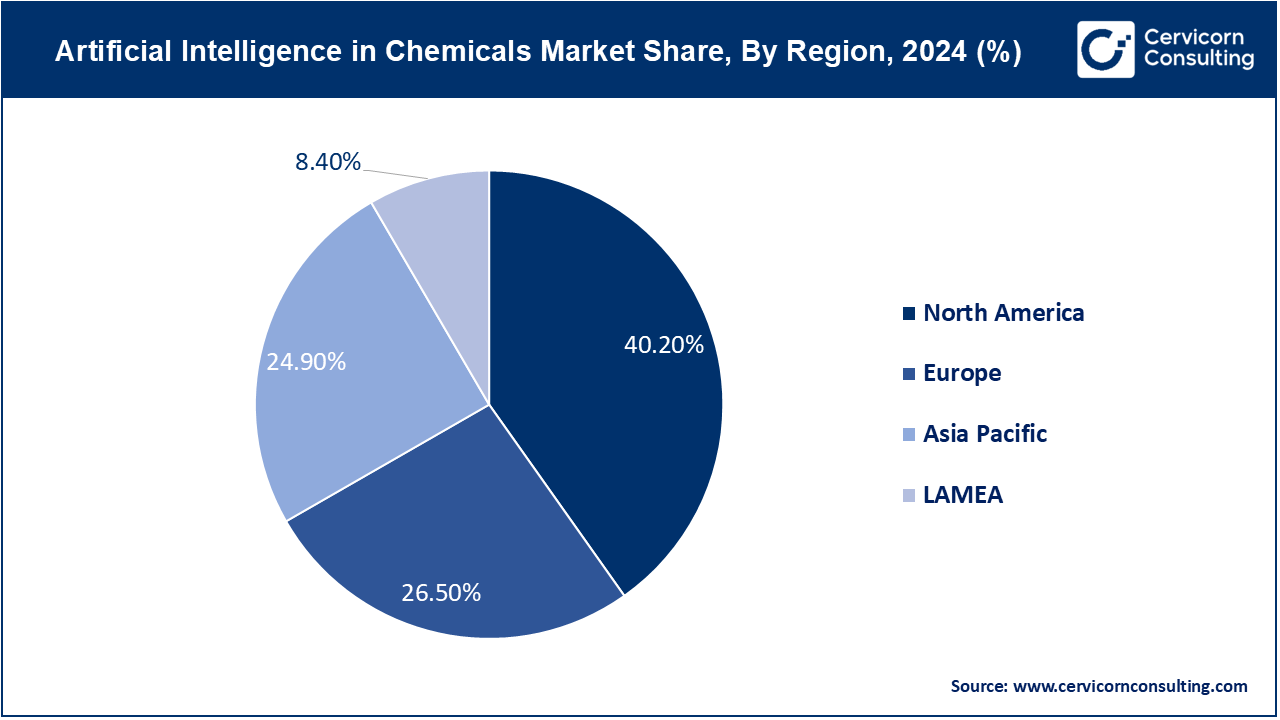

- By Region, The North America region has dominated the market with revenue share of 40.2% in 2024.

- By Region, Asia Pacific is experiencing significant growth by holding revenue share of 24.9% in 2024.

- By End Use, Base Chemicals & Petrochemicals segment has generated highest revenue share of 57.6% in 2024.

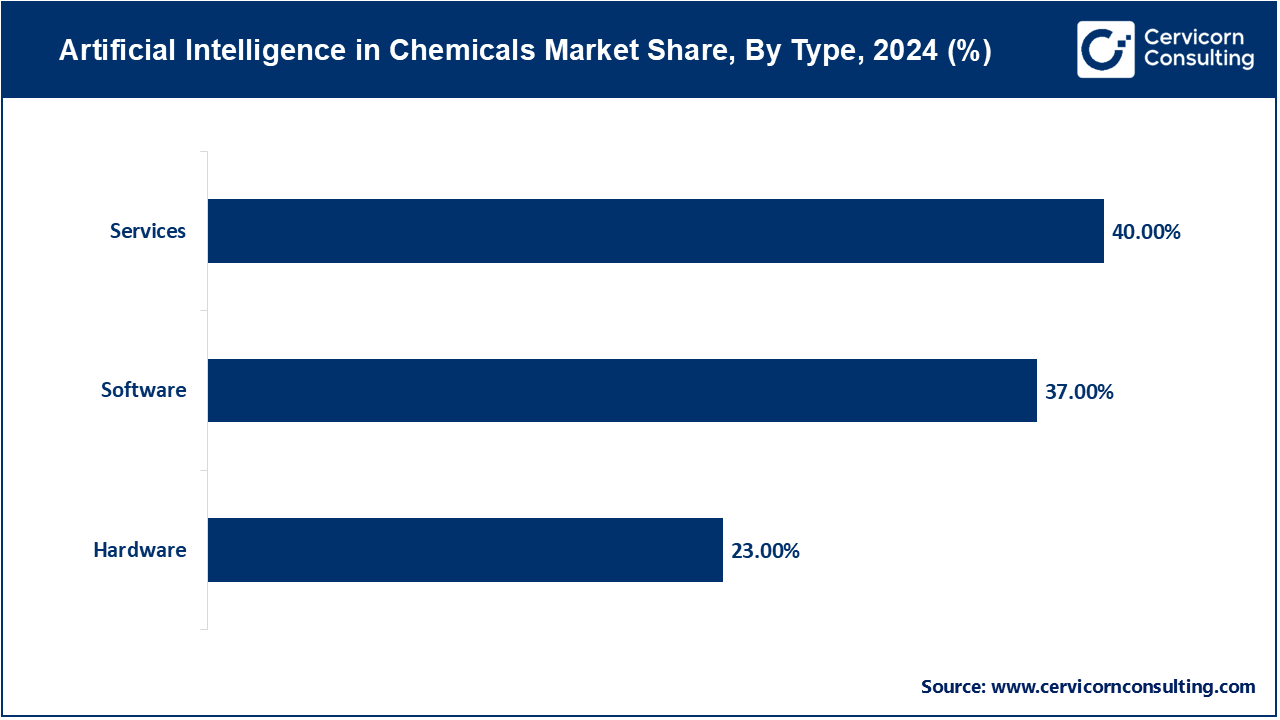

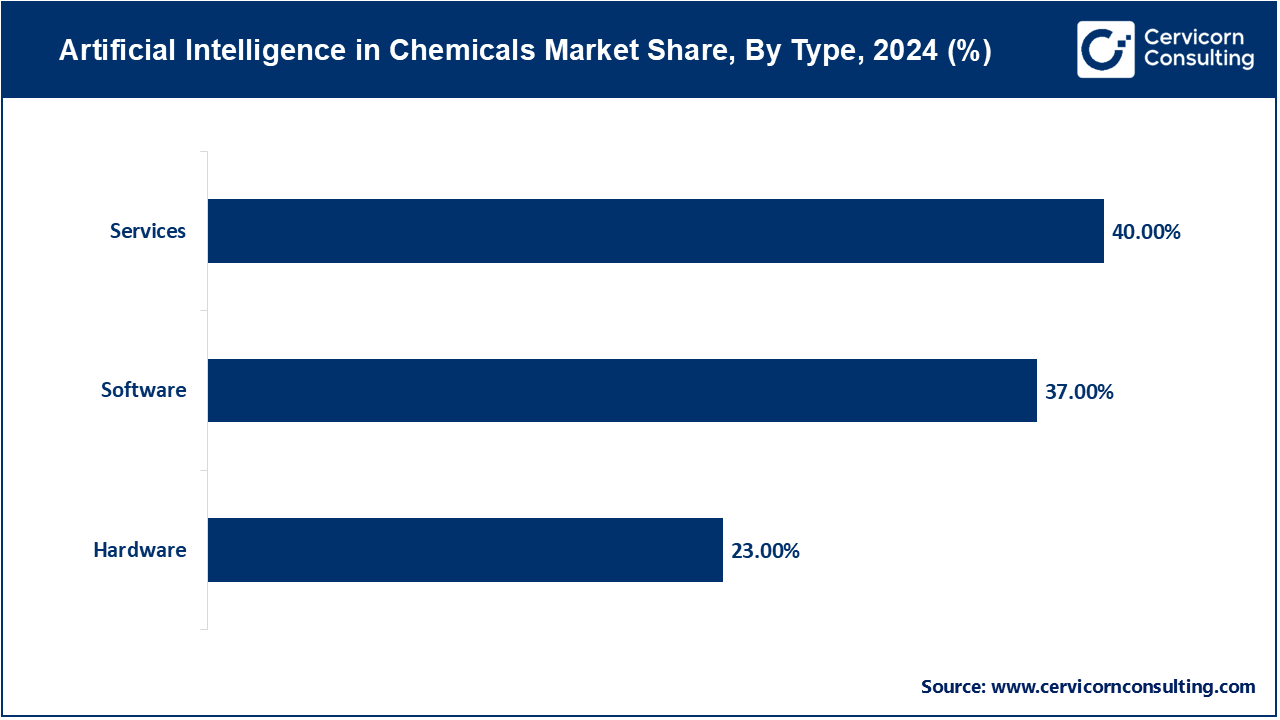

- By Type, The services type segment has reported revenue share of 40% in the year of 2024.

- By Application, The discovery of new materials segment has registered market revenue share of 10.6% in 2024.

- By Application, The others segment has dominated the market by generating revenue share of 30.56% in 2024.

Artificial Intelligence (AI) in Chemicals Market Growth Factors

- Enhanced Efficiency and Productivity: AI and machine learning (ML) technologies significantly enhance efficiency and productivity in the chemicals industry by automating complex tasks. Companies can optimize production processes, reducing the time and resources required. For instance, robotic systems can perform laboratory tests 24/7, accelerating drug discovery and development. This efficiency gain is crucial for maintaining competitiveness in a fast-paced market.

- Improved Predictive Maintenance: AI-driven predictive maintenance tools enable chemical manufacturers to predict equipment failures before they occur. This minimizes downtime and maintenance costs, enhancing operational efficiency. Predictive analytics use data from sensors and historical maintenance records to forecast when equipment needs servicing, thus preventing unexpected breakdowns and optimizing the maintenance schedule.

- Advanced Chemical Discovery and Development: AI and data science accelerate the chemical discovery process by analyzing vast datasets to identify potential compounds and predict their properties. This reduces the time and cost associated with traditional trial-and-error methods. Companies like Pfizer utilize AI to streamline chemical studies and develop novel treatments more quickly, enhancing their ability to innovate and bring new products to market.

- Sustainability and Environmental Benefits: AI technologies contribute to environmental sustainability by optimizing chemical processes to reduce waste and energy consumption. AI-driven process control systems can adjust parameters in real-time to ensure optimal performance, reducing the environmental footprint of chemical manufacturing. According to Nature Communications, AI services can make organizations approximately 63% more environmentally friendly.

- Enhanced Supply Chain Management: AI and ML improve supply chain management by providing better forecasting and inventory management. Companies like Blue Yonder use AI to enhance forecasting accuracy, optimize replenishment, and adjust pricing dynamically. This leads to a more responsive supply chain, reduced inventory costs, and improved customer satisfaction. AI-driven supply chain management ensures that chemical companies can adapt to market changes more effectively, maintaining supply chain resilience and efficiency.

Artificial Intelligence (AI) in Chemicals Market Trends

- Integration of AI in Research and Development: AI is increasingly being integrated into R&D processes within the chemicals market. Companies are leveraging AI to analyze vast datasets and predict the properties of new compounds, accelerating the discovery of innovative chemicals and reducing the time and cost associated with traditional R&D methods.

- Adoption of Predictive Analytics for Maintenance: Predictive analytics is becoming a standard practice for maintenance in the chemicals industry. By utilizing AI to predict equipment failures, companies can schedule maintenance proactively, reducing downtime and extending the life of machinery, which leads to significant cost savings and improved operational efficiency.

- AI-Driven Process Optimization: AI technologies are being used to optimize chemical manufacturing processes. Real-time data analysis allows for the continuous adjustment of production parameters, ensuring maximum efficiency and quality. This trend is leading to more sustainable operations with reduced waste and energy consumption.

- Enhanced Supply Chain Management: The use of AI in supply chain management is transforming how chemical companies handle logistics. AI-driven solutions provide better demand forecasting, optimize inventory levels, and streamline the supply chain, resulting in improved efficiency and reduced costs.

- Sustainability and Environmental Compliance: There is a growing trend of using AI to enhance sustainability efforts in the chemicals industry. AI helps in monitoring environmental impact, optimizing resource use, and ensuring compliance with environmental regulations, making operations more sustainable and socially responsible.

- Personalized Customer Solutions: AI enables chemical companies to offer more personalized solutions to their customers. By analyzing customer data and usage patterns, companies can tailor their products and services to meet specific needs, enhancing customer satisfaction and loyalty.

- AI-Enhanced Safety Measures: AI is being deployed to improve safety in chemical manufacturing. Predictive analytics can identify potential safety hazards and recommend preventive measures. Additionally, AI-driven monitoring systems can ensure compliance with safety regulations, reducing the risk of accidents and improving overall workplace safety.

Report Scope

| Area of Focus |

Details |

| Market Size in 2025 |

USD 2.47 Billion |

| Market Growth Rate |

CAG of 30.43% from 2025 to 2034 |

| Market Size by 2034 |

USD 24.74 Billion |

| Largest Market |

North America |

| Fastest Growing Market |

Asia Pacific |

| Segment Coverage |

By Type, Application, End Use and Regions |

Artificial Intelligence (AI) in Chemicals Market Dynamics

Drivers

Regulatory Pressure for Innovation

- The chemicals industry is under increasing regulatory pressure to enhance safety, reduce environmental impact, and ensure compliance with stringent laws. AI technologies help companies navigate these regulations more effectively by providing advanced data analysis and predictive insights, enabling proactive management of compliance issues and innovation in safer and greener chemical processes.

Rising Demand for Customized Chemicals

- There is a growing demand for customized and specialty chemicals across various industries, such as pharmaceuticals, agriculture, and consumer goods. AI-driven solutions enable chemical companies to rapidly develop and scale the production of tailored compounds, meeting specific customer needs with greater efficiency and precision, thereby driving market growth.

Restraints

High Initial Investment and Implementation Costs

- The integration of AI technologies into chemical manufacturing processes requires significant initial investment. This includes the costs associated with acquiring advanced hardware and software, as well as the expenses related to training personnel and maintaining these systems. For many small and medium-sized enterprises (SMEs) in the chemical industry, these high upfront costs can be prohibitive, limiting their ability to adopt AI technologies.

Data Privacy and Security Concerns

- The deployment of AI in the chemicals market involves the collection and analysis of vast amounts of sensitive data. Ensuring the privacy and security of this data is a major challenge, as breaches can lead to significant financial and reputational damage. Companies must navigate complex regulations and invest in robust cybersecurity measures to protect their data, which can be a restraint on the widespread adoption of AI technologies.

Opportunities

Enhanced Predictive Maintenance

- AI offers significant opportunities in predictive maintenance, which can greatly reduce downtime and increase the efficiency of chemical plants. By using AI algorithms to analyze data from equipment sensors, companies can predict when machinery is likely to fail and schedule maintenance before breakdowns occur. This not only extends the life of the equipment but also ensures continuous and optimal operation, leading to substantial cost savings and improved productivity.

Sustainable Chemical Production

- AI can drive innovation in sustainable chemical production processes. By optimizing reactions and reducing waste, AI technologies can help companies develop greener production methods. This aligns with the growing demand for environmentally friendly practices and products. For instance, AI can help design new catalysts that increase yield while minimizing energy consumption and by-products, contributing to sustainability goals and enhancing a company’s market position in the eco-conscious consumer landscape.

Challenges

Data Quality and Integration:

- One of the primary challenges in implementing AI in the chemicals market is ensuring high-quality, consistent, and integrated data. AI models require vast amounts of accurate data to function effectively. In the chemicals industry, data often comes from diverse sources and systems, leading to inconsistencies and integration issues. Poor data quality can result in unreliable AI outputs, hindering decision-making processes and reducing trust in AI solutions among stakeholders.

Skill Gap and Workforce Adaptation:

- Another significant challenge is the skill gap in the workforce. Implementing and managing AI technologies requires specialized knowledge in data science, machine learning, and domain-specific expertise in chemistry and chemical engineering. The current workforce may lack these skills, necessitating extensive training and education programs. Additionally, there may be resistance to adopting new technologies, further complicating the integration of AI into existing workflows and business practices.

Artificial Intelligence (AI) in Chemicals Market Segmental Analysis

The AI in chemicals market is segmented into type, application, end use and region. Based on type, the market is classified into hardware, software, and services. Based on application, the market is classified into discovery of new materials, production optimization, pricing optimization, and others. Based on end use, the market is classified into base chemicals & petrochemicals, specialty chemicals, and agrochemicals.

Type Analysis

Hardware: The hardware Segment has covered market share of 23% in 2024. The hardware segment in the AI chemicals market includes specialized processors, sensors, and devices essential for AI implementation. The trend towards edge computing and increased processing power in AI hardware is driving innovation in real-time data analysis and automation. Advanced AI hardware enhances precision in chemical experiments, supports large-scale simulations, and accelerates complex computations in research and development.

Software: In 2024 this segment has generated second highest market share of 37%. AI software in the chemicals market encompasses machine learning algorithms, data analytics platforms, and predictive modeling tools. The growing adoption of AI-driven software for optimizing chemical processes, improving safety, and enhancing product quality is a significant trend. Software advancements enable more accurate simulations, faster drug discovery, and efficient management of supply chains, thereby driving operational efficiency and cost reduction.

Services: The services segment has registered highest market share of 40% in 2024. The services segment involves consulting, implementation, and maintenance of AI systems in the chemicals industry. There is a rising demand for AI integration services to ensure seamless adoption and customization of AI solutions to meet specific industrial needs. The trend towards outsourcing AI expertise and managed services is driving growth, as companies seek to leverage external expertise for continuous improvement and innovation in their AI initiatives.

Application Analysis

Discovery of New Materials: The discovery of new materials segment has reported market share of 10.6% in 2024. AI accelerates the discovery of new materials in the chemicals market by utilizing machine learning algorithms to predict material properties and behaviors. This speeds up R&D, reduces costs, and enables the development of innovative products with enhanced performance and sustainability, meeting the growing demand for advanced and eco-friendly materials.

Production Optimization: This segment has accounted market share of 10.22% in 2024. In production optimization, AI enhances efficiency and reduces waste by analyzing data from various stages of the manufacturing process. Predictive analytics and machine learning models identify bottlenecks, optimize production schedules, and fine-tune operations, leading to increased yield, lower costs, and improved overall productivity in chemical manufacturing.

Pricing Optimization: The pricing optimization segment has calculated market share of 10.15% in 2024. AI-driven pricing optimization leverages data analytics to set competitive prices for chemical products. By considering factors such as market demand, competitor pricing, production costs, and customer behavior, AI algorithms help companies maximize profits, improve market share, and respond dynamically to market changes, ensuring optimal pricing strategies.

Load Forecasting of Raw Materials: This segment has confirmed market share of 9.95% in 2024. AI in load forecasting predicts the demand and supply of raw materials, helping chemical companies maintain optimal inventory levels. Machine learning models analyze historical data, market trends, and external factors to accurately forecast raw material needs, minimizing stockouts and overstock situations, and ensuring a smooth and cost-effective supply chain.

Product Portfolio Optimization: The product portfolio optimization segment has garnered market share of 9.4% in the year of 2024. AI aids in product portfolio optimization by analyzing market trends, customer preferences, and competitive landscapes. This enables chemical companies to streamline their product offerings, focus on high-demand and high-margin products, and identify gaps in the market, ultimately enhancing profitability and aligning with strategic business goals.

Feedstock Optimization: In 2024 this segment has achieved market share of 9.14%. AI optimizes feedstock utilization by analyzing feedstock properties, availability, and costs. Advanced algorithms recommend the best mix of raw materials for production, ensuring cost efficiency, sustainability, and consistent product quality. This helps chemical manufacturers adapt to fluctuating raw material markets and reduce overall production costs.

Process Management & Control: The process management and control segment market share was valued at 9.98% in 2024. AI enhances process management and control by providing real-time monitoring and predictive maintenance. Machine learning models detect anomalies, predict equipment failures, and suggest optimal operational parameters. This ensures smooth and efficient production processes, reduces downtime, and extends the lifespan of machinery, leading to cost savings and higher productivity.

End Use Analysis

Base Chemicals & Petrochemicals: This segment has captued highest market share of 57.55% in 2024. In the base chemicals and petrochemicals sector, AI enhances production efficiency, safety, and sustainability. It optimizes feedstock usage, predicts equipment failures, and streamlines operations through real-time data analytics. AI-driven innovations help reduce costs, improve yield, and ensure compliance with environmental regulations, driving the adoption of AI in this segment.

Specialty Chemicals: The specialty chemicals segment has reported market share of 26.35% in 2024. AI in specialty chemicals focuses on innovation and customization. Machine learning algorithms enable the development of tailored chemical formulations, enhancing performance and meeting specific customer needs. AI also optimizes production processes, reduces time-to-market, and improves quality control, making it a key driver for growth and competitiveness in the specialty chemicals industry.

Agrochemicals: The agrochemicals has confired 16.1% market share in 2024. AI revolutionizes the agrochemicals market by improving crop protection, yield prediction, and resource efficiency. Advanced analytics and machine learning models aid in the development of more effective and sustainable agrochemical products. AI-driven precision agriculture techniques optimize pesticide and fertilizer usage, enhancing productivity and supporting sustainable farming practices, thus driving the market forward.

Artificial Intelligence (AI) in Chemicals Market Regional Analysis

Why North America is leading in the artificial intelligence (AI) in chemicals market?

The North America market size is expected to reach around USD 9.95 billion by 2034 increasing from USD 0.76 billion in 2024 with a CAGR of 30.50%. North America leads in the AI in chemicals market due to its advanced technological infrastructure and significant investments in AI research and development. The region’s chemical industry benefits from strong collaboration between tech companies and chemical manufacturers. The presence of major AI and chemical companies, along with supportive government policies, accelerates AI adoption. Key drivers include optimizing production processes, reducing operational costs, and enhancing safety standards. The U.S. and Canada are the primary contributors, with a focus on innovation and sustainability in chemical manufacturing.

Why Asia Pacific is experiencing significant growth in the artificial intelligence (AI) in chemicals market?

The Asia Pacific market size is calculated at USD 0.47 billion in 2024 and is projected to grow around USD 6.16 billion by 2034 with a CAGR of 30.62%. The Asia-Pacific is experiencing rapid growth in the AI in chemicals market, driven by the region’s expanding industrial base and increasing demand for chemicals. China, Japan, and South Korea lead in AI adoption, leveraging advanced technologies to optimize production, improve quality control, and reduce costs. The region benefits from significant investments in AI and a growing focus on smart manufacturing. Additionally, supportive government policies and initiatives to promote digitalization and innovation in the chemical industry contribute to the market’s expansion, making Asia-Pacific a key player in the global AI in chemicals market.

Europe Artificial Intelligence (AI) in Chemicals Market Trends

The Europe market size is measured at USD 0.50 billion in 2024 and is expected to grow around USD 6.56 billion by 2034 with a CAGR of 30.58%. Europe AI in chemicals market is driven by stringent environmental regulations and a strong focus on sustainability. The region is home to several leading chemical companies investing in AI to enhance production efficiency, reduce emissions, and develop eco-friendly products. Germany, the UK, and France are at the forefront of AI adoption, supported by robust R&D activities and government initiatives promoting digital transformation. The European Union’s emphasis on Industry 4.0 and smart manufacturing further propels AI integration in the chemical sector, aiming for greener and more efficient operations.

LAMEA Artificial Intelligence (AI) in Chemicals Market Trends

The LAMEA market size is forecasted to reach around USD 2.08 billion by 2034 from USD 0.16 billion in 2024 with a CAGR of 30.41%. The AI in chemicals market in LAMEA is growing, driven by increasing industrialization and the need for enhanced production efficiency. In Latin America, Brazil and Mexico lead AI adoption, focusing on optimizing manufacturing processes and improving competitiveness. The Middle East, with countries like Saudi Arabia and UAE, invests in AI to boost the petrochemical sector and diversify economies. Africa, although at an early stage, is gradually embracing AI to enhance chemical production and sustainability. Government initiatives and international collaborations play a crucial role in driving AI integration in the LAMEA chemical industry.

Artificial Intelligence (AI) in Chemicals Market Top Companies

- BASF SE

- Dow Inc.

- ExxonMobil

- Royal Dutch Shell plc

- SABIC

- LyondellBasell Industries

- Air Products and Chemicals, Inc.

- Johnson Matthey

- Eastman Chemical Company

- Solvay SA

- Mitsubishi Chemical Holdings Corporation

- Arkema

- Evonik Industries

- Covestro AG

- Clariant

New players like Covestro AG and Clariant are leveraging AI for process optimization, sustainability, and product innovation. Covestro focuses on developing advanced material solutions and improving production efficiency, while Clariant enhances chemical manufacturing through AI-driven process improvements. Dominating players such as BASF SE, Dow Inc., and Royal Dutch Shell plc drive AI adoption through significant investments in R&D, strategic collaborations, and innovations. For instance, BASF partners with tech companies to enhance AI capabilities, Dow Inc. uses AI for predictive maintenance and supply chain optimization, and Shell employs AI to minimize environmental impact and improve operational efficiency. These efforts collectively propel the AI in chemicals market forward.

CEO statements

- Martin Brudermüller, CEO of BASF SE: "AI is a game-changer for the chemical industry, enabling us to enhance efficiency, drive innovation, and develop sustainable solutions that meet the evolving needs of our customers."

- Jim Fitterling, CEO of Dow Inc.: "By integrating AI into our operations, we are able to predict maintenance needs, optimize supply chains, and reduce production costs, ultimately delivering greater value to our stakeholders."

- Darren W. Woods, CEO of ExxonMobil: "AI technologies are essential for advancing our capabilities in production optimization and environmental stewardship, ensuring that we remain at the forefront of the energy and chemicals sector."

- Ben van Beurden, CEO of Royal Dutch Shell plc: "Our investment in AI is crucial for minimizing our environmental impact, enhancing operational efficiency, and driving forward our commitment to sustainability."

- Yousef Al-Benyan, CEO of SABIC: "Harnessing the power of AI allows us to innovate and optimize our processes, ensuring that we continue to deliver high-quality products while maintaining our competitive edge in the global market."

- Matthias Zachert, CEO of Covestro AG: "AI is pivotal in our efforts to develop advanced material solutions and achieve greater production efficiency, supporting our mission to push the boundaries of what's possible in the chemical industry."

Recent Developments

- In March 2024, AWS and NVIDIA joined forces to enhance computer-aided drug discovery using new AI models. Their collaboration aims to model the efficacy of new chemical molecules, predict protein structures, and understand drug molecule interactions with biological targets, significantly advancing pharmaceutical R&D.

- In January 2024, a robotic chemistry lab partnered with Google AI to predict and synthesize novel inorganic materials. This collaboration leverages advanced algorithms and automation to accelerate material discovery and development.

- In November 2023, GE Vernova’s Gas Power business and Duke Energy announced the nation’s first 100% green hydrogen-fueled peaking power plant. GE Vernova will support the development of an end-to-end green hydrogen system at Duke Energy’s DeBary plant in Volusia County, Florida.

- In October 2023, NobleAI partnered with Azure Quantum Elements (AQE), a Microsoft cloud service integrating High-Performance Computing (HPC), AI, and quantum computing. This collaboration combines AQE's advanced molecular simulation and HPC features with NobleAI's AI-driven solutions.

- In May 2023, Google Cloud unveiled two new AI-powered life sciences solutions aimed at accelerating drug discovery and precision medicine for biotech companies, pharmaceutical firms, and public sector organizations. The Target and Lead Identification Suite helps identify amino acid functions and predict protein structures, while the Multiomics Suite speeds up genomic data discovery and interpretation.

- In May 2023, the chemical industry initiated a pilot project with Siemens to reduce carbon emissions in its supply chain. This collaboration, part of the Together for Sustainability initiative, involves 47 chemical companies using Siemens' "Sigreen" solution to digitally exchange Product Carbon Footprint (PCF) data.

Market Segmentation

By Type

- Hardware

- Software

- Services

By Application

- Discovery of new materials

- Production optimization

- Pricing optimization

- Load forecasting of raw materials

- Product portfolio optimization

- Feedstock optimization

- Process management & control

- Others

By End Use

- Base Chemicals & Petrochemicals

- Specialty Chemicals

- Agrochemicals

By Region

- North America

- APAC

- Europe

- LAMEA